One of the top producers of customized power generation machinery, Collicutt Energy Services Corp. provides high-efficiency prime power CHP systems to standby power units, and engineers, designs, and produces complete power solutions. To ensure power solutions are the best in their class, the company’s technical and manufacturing teams continually strive to improve the quality of products and services while fostering strategic alliances that guarantee strong, capable and reliable results.

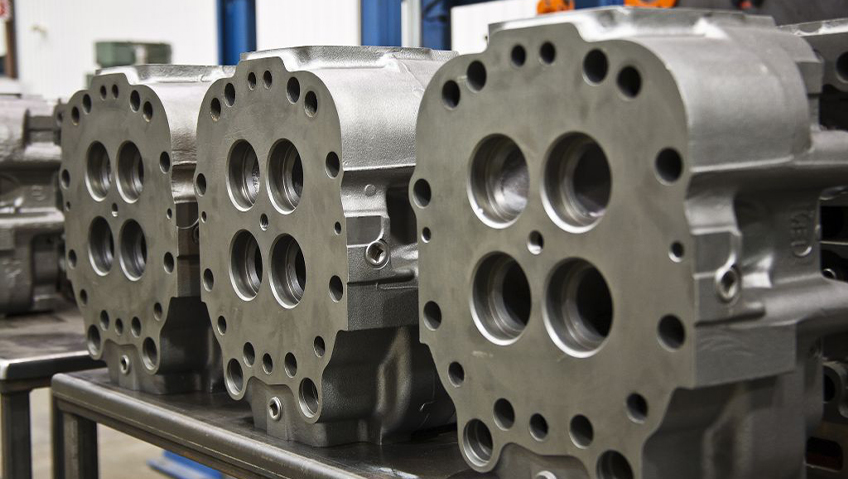

In business for 38 years, Collicutt started in the gas industry with gas compression maintenance as its mainstay, and continues to operate with the same philosophy it has held since its founding as an engine company in 1986. The company services and packages engines of all makes, models, and industries, and offers everything from inspections to zero hour rebuilds. Whether it’s rebuilding compressors, generators, pumps, and transmissions or servicing engines, Collicutt provides clients with valuable solutions.

While being a long-time family-run company is one of the keys to the company’s ongoing success, the leadership also cites numerous other reasons. “We treat our employees like family, we’re very agile, and we’re able to make decisions fast, because we have a fairly flat management structure,” says David Taylor, Vice President of U.S. Operations.

“We don’t report to a public company,” adds Ryan Krutzfeldt, Vice President of Operations. “The owner is very entrepreneurial, so if the decision is we want to invest in this or do that or buy this tool, as long as it makes sense, there’s no red tape or bureaucracy to have to go through a whole bunch of steps. It makes us faster and better.”

One of Collicutt’s core values is also soundly reflected in the company’s work ethic, he says. “Steven Collicutt started this company from nothing, is still running it, and has a passion to do so. We’re always looking for better and more innovative ways of doing things.”

Being faster, better, and more innovative includes embracing practices such as fuel blending that help contribute to a more sustainable future, with one major advantage being the decrease in greenhouse gas emissions. Biogas is a renewable energy source that is carbon neutral and is produced through the breakdown of organic materials. Blending biogas with fossil fuels like natural gas lowers the fuel’s total carbon impact, an extremely beneficial quality for businesses looking to reduce their environmental effect and meet sustainability targets.

Biogas, which is what Collicutt typically blends with natural gas, is a natural by-product of composting and decomposing waste. Generally speaking, if not handled properly, the gas from the composting ends up in the atmosphere.

“By capturing the methane gas—which is the worst GHG emission in there—it prevents that from going into the atmosphere and contributing to those emissions,” says Taylor. “If you look at it as a whole, in many jurisdictions this biogas is considered carbon neutral, so you can take that then and blend it with natural gas to reduce the carbon footprint of any facility. It not only helps you from that perspective, but it also helps the environment because it’s not being vented.”

Blending also results in better engine performance, he adds. If you use only biogas, it’s not necessarily the best or most efficient gas for a high-performance engine, so blending it with natural gas creates a better engine profile and more efficient engine operation and electricity production.

Another product highlight is the company’s CHP products, which function as hub replacements for resource-intensive and short-lived battery systems. “Our product, called the kinetic power pack, uses kinetic energy, so it’s always spinning,” explains Krutzfeldt. “It works with capacitors rather than batteries. During a power interruption—whether in hospitals, data centres, a semiconductor production facility, anywhere that needs uninterrupted power—this system of kinetic power that’s constantly moving the momentum of that spinning mass carries them through any power outage.”

Referred to as D-UPS—Dynamic Uninterruptible Power Supply— it’s also known as a flywheel energy storage power system or a dynamic rotary uninterruptible power supply (DRUPS). For businesses with strict performance tolerances that rely on consistent electric power, DRUPS provides a reliable backup power source.

Along with its numerous innovative products, Collicutt offers a variety of specialized services to its clientele including natural gas and diesel generator maintenance and repairs, engine and component rebuilds, and natural gas compression services. “For our fracking customers or generator customers, if they have an issue with their engine or the ancillary equipment, whether it be a generator or a frack pump, we’re there to overhaul the engine, repair, and fix, as needed,” says Krutzfeldt.

Collicutt also provides testing equipment to help customers determine if there is a problem, what is the problem, and if are there other problems that need correcting. “Once we’re done with that, we test it again to make sure it’s field ready before it goes to the field, and doesn’t fail.”

This attention to service was also evident during COVID when the company moved to a virtual enabled business. “We put a lot of effort into being able to run our business from the cloud wherever possible,” says Taylor. “Because we did that when COVID hit where a lot of businesses were negatively impacted, during this period we actually were able to grow our business because we were already enabled virtually. I think that’s a strategic benefit that Collicutt has.”

Another challenge—and a common one across many industries—is the struggle to find qualified skilled labourers, particularly in the face of looming industry retirements. In this area, “we’re trying new things all the time. We’re looking at overseas people and we look at head-hunters and recruiting firms,” says Krutzfeldt.

The company is also setting up a scholarship at the local college to entice and retain younger people to the field.

“Building on that a little bit, we’ve implemented a program in the U.S. for hiring technicians, junior or apprentice level technicians, where they get a set of tools,” says Taylor. “Typically, when somebody comes out of school and is getting into the industry, they can’t afford the thousands of dollars they have to spend on tools. We have a three-year training program, and at the end of the three-year training program, they get to keep the tools we provided so long as they’re still with us and they’ve passed all the training we’ve put them through.”

In Canada, there is also a program that brings in high school students who have shown an interest in the trade, allowing them to earn credit toward graduation, adds Krutzfeldt. “That is their entry into the trade.”

As it becomes more vital to attract younger workers into the industry, letting students know about the many benefits of not following a traditional four-year university path is important, especially for parents who may still hold onto the stigma of trades versus higher education for their children.

“You come out of high school, you register as a trade, and in four years, you’re making $40 to $50 an hour,” he says. “Plus, all of your school is paid for. I think not very many people know this. And I think students need to start learning this in high school, instead of going into debt for university and maybe not doing what they want to be doing. [Trades] can be a good alternative for some people.”

Just as not everyone is cut out for the trades, not everyone is suited for a university path either, but knowing the full range of options—along with their potential salary earnings—can make a huge difference for both students and their families when armed with all the facts.

“That needs to change because there is a big shortage of skilled workers in a lot of industries,” says Krutzfeldt. “It’s going to be scary when Baby Boomers are starting to retire… prices will go up because labor is going to be in high demand.”

Collicutt, both in Canada and the U.S., plans to continue to seek new, young employees while maintaining the company culture that is so important to its success, particularly when it comes to attitude and outlook. “We try to train our everybody in our organization to have that entrepreneurial spirit,” says Krutzfeldt. “We look for the problem and we fix that issue.”

One example of this commitment involves a customer that called for a generator repair who had been told by a competitor that the engine was past the point of fixing. “They wanted a second opinion. We took a look and found we were able to fix it for probably half of what it would cost for the customer to get a brand new unit in there,” he says. “So the customer was happy, and we’ve now gained their trust in our business. It’s about being honest; it’s not just taking the easy path of getting a new generator. Easy isn’t always the correct solution.”

This is why the company’s fracking clientele and power gen clientele keep coming back, Krutzfeldt adds. “We like repeat customers. Keep your customers happy and always be finding them good service.”

And keeping those customers satisfied has gone a long way toward making Collicutt the business it is today. “We provide solutions,” says Taylor. “We don’t sell the products, and we don’t sell widgets. We love to see what the customer needs, expand from what they’re asking for to understand what the real problem is, and provide a complete solution. I think that’s a huge differentiator for us.”