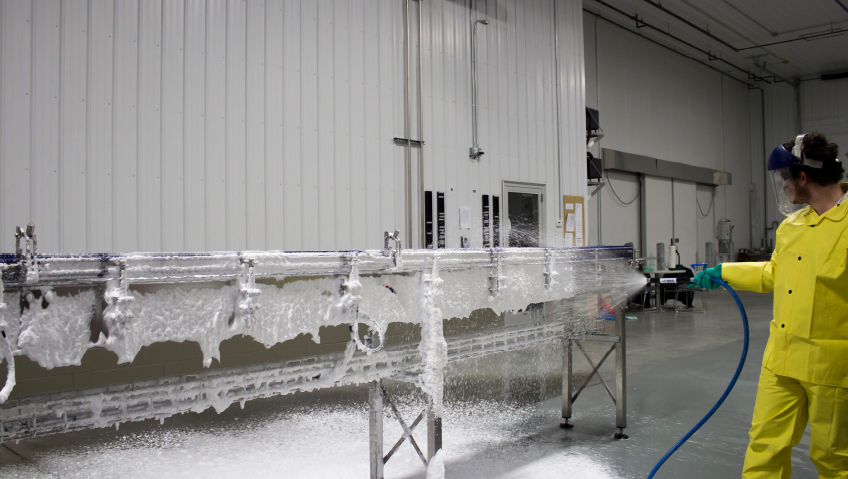

Many industries rely on FOAMit’s outstanding cleaning equipment to keep end users safe and protected from potentially harmful pathogens in a variety of spaces. At its core, FOAMit designs and manufactures equipment to manage and apply chemicals.

Achieving cleanliness in food manufacturing facilities, institutional spaces, and industrial areas means using quality equipment to achieve quality results. Providing premium cleaning equipment, the FOAMit team is known for durable machines, reliability, and outstanding customer service. Helping to reduce customers’ long-term overhead expenses in this way, the company, as a business-to-business partner, frees its clients to focus on better serving their respective markets’ needs.

FOAMit has a responsibility to bring reliable cleaning equipment to a range of industries, as its machines handle a variety of cleaning and disinfection suspensions like mists, sprays, gels, foams, and more. Sectors served include agriculture, food processing, breweries and wineries, property restoration, healthcare, aviation and travel, hospitality, and others. One of the most interesting outcomes of serving so many industries is that applications in one often lead to innovation in another, and so the company’s customers obtain value from the team’s entire reach.

As an innovator, FOAMit is prolific; in the past year, the company has introduced a generous selection of new equipment. These include its utility-free, airless, footwear sanitizing unit that comes in three models, of which one offers a boot scrubber option. The unit is easy to set up and works entirely mechanically, allowing users to implement it anywhere around food plants, poultry barns, and other areas. This unit sanitizes footwear of potential pathogens, preventing cross-contamination between food production zones.

The company’s new Equip Series battery portable units vastly improve on older iterations of a similar product, the unit’s new lithium-ion portable batteries allow greatly enhanced application and wider use. Operational ease and portability are just two of the benefits that these units provide. As part of FOAMit’s commitment to keeping customers’ production facilities operational by creating products that are simple and fast to maintain, these units are also easy to replace and repair.

Similarly, a new drum rinse system is designed to triple-rinse 55-gallon drums for reuse and recycling. “We are very excited about our [drum rinse system]. It’s easy to use and saves our customers labor and water for an otherwise labor- and resource-heavy—yet necessary—task,” says Marketing Manager Sam Carbaugh of the button-activated system that is transforming operations for many customers. The product also significantly contributes to the environmental sustainability of companies’ operations.

FOAMit products are also user-friendly. They are simple to use, and the company shares information and guidance that makes ownership a pleasure. Its website is full of useful resources covering every aspect of product operation and other information.

While datasheets and user manuals provide written guidelines, FOAMit’s instructional videos provide detailed, step-by-step, visual guidance on operating and handling the equipment. This includes instructions on replacing valves, air regulators, and other mechanical elements. And customers know that, should they need further support, the FOAMit team is just a phone call away, always ready to handle customer questions.

Focused on strategic growth, the company has taken the time to ensure that its systems and capabilities are developed in a way that supports expansion. To achieve this, its teams are continually innovating and adapting to market demand. “Our design team is always keeping an eye out for what the next needs are for our customers and how we can make those in ways that are durable and long-lasting, but also cost-effective,” says Carbaugh.

It comes as no surprise that the company is on a winning streak with its focus on innovation and excellent customer care. “We have a high level of customer service. Our response rates are, I think, leading in the industry,” says Laura Klaasen, Director of Sales. This enables its customers and end users to remain consistent, securing uptime and productivity, which of course reflects in everybody’s bottom lines.

Whether it means providing audit support or shipping replacement parts to customers on short notice, FOAMit is always there to provide whatever is necessary to keep customers achieving their goals. Moreover, the company emphasizes effective and meaningful communication, leaning in to understand customer needs. “We try to speak our customers’ languages. We really learn what’s important to them,” Klaasen adds.

Navigating customers ranging from small businesses to large corporate enterprises makes FOAMit the ideal partner. Understanding customers’ operational systems as well as cultures gives the team a fundamental understanding of how to serve them in a way that enhances overall operations. Naturally, this approach extends to supporting clients through difficult situations and to expanding its capabilities when customers need their machines to do more. By embracing these conversations, FOAMit is allowing its customers’ applications and work environments to guide its evolution.

This is a multi-generational company under second-generation leadership, and the third generation has already taken up its position. Founded in a garage, the company grew from small beginnings into a flourishing business, outgrowing four buildings in its time. Today, the company’s founder still maintains a garage at its current facility to continue innovating and creating.

FOAMit’s mission of ‘making it better’ reaches beyond supplying top-notch chemical equipment and service. The team contributes to charitable causes like organizations providing children with meals, helping those working with children in foster care, and many others. It also contributes to Habitat for Humanity and local community clean-up drives. FOAMit is also an active participant in the Free Wheelchair Mission, an organization driven to give physically and economically vulnerable people around the world desperately needed access to wheelchairs that may not otherwise have been available to them.

Ensuring that it remains relevant, the company implemented an enterprise resource planning (ERP) system four years ago that has led to expanding lean manufacturing protocols and improving efficiency and output. Against this backdrop, designing and developing products with the ideal value, ease, and cost of ownership in mind means gaining more customers while making life and business easier for end users. “We are focused on growth,” says Klaasen about the firm’s plans to continue expanding its market share.