Company President John Coyle has over 40 years of experience in the box manufacturing business and, alongside a team of experts, he has built McLeish Corr-A-Box Packaging into a local leader in the ultra-competitive corrugated packaging industry.

~

The company, McLeish Corr-A-Box, was founded in 1977 as a joint venture between John’s father Gordon Coyle and his partner Vern Hartwick. John worked for his father for a number of years, eventually purchasing three packaging plants in Ontario in 2001. These were: McLeish Containers in Concord, Brown Packaging in Burlington, and St. Catherine’s Corrugated Containers. John ran these plants until 2009 when he bought McLeish Corr-A-Box.

He had a keen sense for how to remain profitable during an economic down-turn. The unstable climate at the time prompted him to merge his Concord plant into the newly acquired McLeish Corr-A-Box plant, and his St Catherine’s plant into his Burlington plant. “I thought the best way to make money was to be busy, so I made my plants busy,” says John.

“Know when you’re not making money,” is something which John considers a guiding principle, and he notes that sometimes it’s okay to do work for the sake of getting your foot in the door or to further your relationship with a client. “It’s okay to not make money on every project, just know when you’re not,” he shares. Knowing when to merge four plants into two gave John the ability to invest in equipment, and as a result, under his leadership, McLeish Corr-A-Box has seen steady growth for eight years running.

“The business is about 75 percent packaging, about 25 percent display work,” notes John. The company designs and manufactures corrugated boxes for packaging and point of purchase displays for retail and merchandising. In both aspects, Corr-A-Box is an expert in both structural and graphical design, creating solutions that are highly functional, stable and imaginative to suit the marketing and distribution needs of the firm’s many satisfied customers.

When it comes to packaging, aesthetics and structure are equally important. McLeish Corr-A-Box builds sturdy boxes with layered cardboard, making them some of the strongest products on the market and keeping the products within safe during transport and storage. Corrugated packaging is the most cost-effective solution for solid, stable, and safe packaging, and Corr-A-Box’s boxes are some of the best in the business.

But it doesn’t end with functionality; the design experts at McLeish work with customers to build custom box designs complete with logos and branding. For the point of purchase sector, the design team builds beautifully imaginative, colour-rich displays that enhance a product’s retail visibility. Whatever the product, McLeish has the expertise to turn packaging into a marketing and branding engine for its customers.

In an industry where a few fully-integrated goliath companies control 80 percent of the market, McLeish Corr-A-Box remains competitive by putting the customer first. “We jump through hoops to keep customers happy, and we’re known to bail people out when they’re in a jam,” says John, recalling a recent job where a client needed product by eight o’clock the very next morning. An average delivery for McLeish Corr-A-Box is three days or less, when during peak times the big integrated companies often quote five to six weeks. “A customer can’t have a line down for any amount of time,” John explains. The ability to deliver next-day in certain special cases gives Corr-A-Box a leg up on the competition, and the team is dedicated to delivering on promises and going above and beyond to keep customers happy and profitable.

In many cases, McLeish Corr-A-Box has the capacity to do what the larger companies cannot. While the Corr-A-Box plant uses some of the most sophisticated equipment available, the company doesn’t suffer the drawback of having a constant line-up of 12 or more hours of material on conveyors. This gives the team the flexibility to change a line-up quickly and adjust the priority of certain orders on the fly. The company ships day and night, and with a weekend shift, can easily keep ahead of a busy week.

A big part of staying ahead is being able to coordinate closely with the firm’s supply chain. John and two partners together own 1/3 of the company that supplies 100 percent of McLeish Corr-A-Box’s corrugated material. Being partially integrated in this way allows the firm to share the advantages of the larger fully integrated companies without losing touch with its customer-focused model. “We’re integrated, but we’re not,” says John. It’s just the right trade-off for the way Corr-A-Box does business.

With those same partners in 2012, John invested in Greenpac, North America’s first 100 percent recycled linerboard mill. Greenpac is the largest lightweight linerboard facility in North America using the most sophisticated recycling technology to produce 540,000 tons of linerboard, made from 100 percent recycled material, annually. Corr-A-Box has worked hard to ensure that its products adhere to the guidelines set by the Sustainable Forestry Initiative and the Forestry Stewardship Council. Experience allows the team to minimize material waste; they invest in equipment and initiatives that further reduce the material used in their products, and they’ve helped fund the Paper and Paperboard Products Environmental Council (PPEC). McLeish Corr-A-Box cares about environmental sustainability, and has invested the money to prove it.

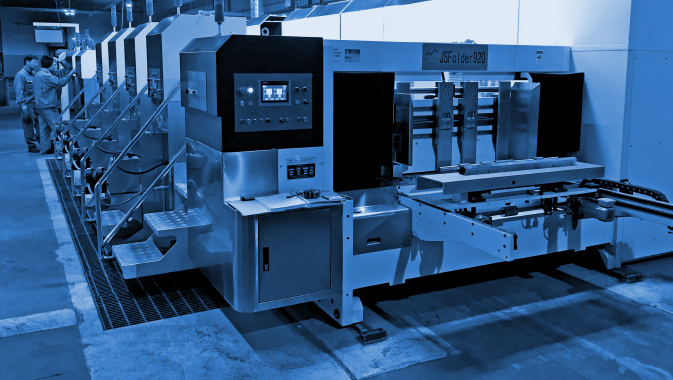

John understands that expansion and growth are key to remaining competitive in the down-and-dirty box business. Recently, he has invested in a state-of-the-art four-colour box-making piece of equipment called a four-colour flexo folder gluer. This giant, leading-edge machine cuts, prints in colour, and folds boxes, surpassing the speed and quality of its predecessors, and is the first of its kind in North America. This machine will allow the company to increase production and the quality of its boxes. For McLeish Corr-A-Box, it’s all about creating a quality product it can stand by proudly, and investing in the newest, best technology available is the way to get there.

At his Corr-A-Box plant, John employs 85 people – 55 in the plant, 11 on the sales team, and the rest in estimating, customer service, and design. “Two of [Corr-A-Box founder] Vern Hartwick’s daughters still work for me. Some of my employees have been here the whole 40 years.” He believes not only in maintaining solid relationships with his customers but also with his staff. “Even now, while I’m talking to you, my door is wide open,” notes John.

He feels that a driving force behind the success of his company is that he doesn’t cut corners when it comes to taking care of his workforce. He keeps his sales people productive by treating them fairly and making sure they have access to a solid support team. “I could cheapen things up a little, but then good sales people wouldn’t want to work for me.” Says John, “I shouldn’t be greedy, and my company shouldn’t be greedy.”

John has seen his share of ups and downs in business, but he feels optimistic. “I travel to Florida five to six times a year and the American people seem very positive for the first time in seven or eight years. In the Southern Ontario market, we’re feeling it.”

He runs a state-of-the-art operation by a set of old principles that seem all but forgotten in modern business; with an open-door policy and the occasional last minute hustle to keep a customer on track, McLeish Corr-A-Box is truly a unique company. “At the end of the day, if you want to stay in business you have to have the right colour of ink.”