Calvary Robotics is a world leader in the design and development of automation systems and robotics platforms. The company is built on four individual but complementary business units that are distinct in their expertise but combined, bring state-of-the-art systems to the robotics and automation markets. Calvary will manage a customer’s project through every stage of its lifecycle from inception to market as well as provide value-added services and support to ensure their customers’ expectations and returns on investment are met or exceeded.

~

Calvary Robotics was founded in 1994 by Owner and Chief Executive Officer Mark Chaney as a small startup design engineering firm. Today, the company employs over 250 people, has offices in South Carolina and Malaysia, in addition to the original Rochester HQ location, and has divided its operations into specialized business units. Calvary believes that it is the synergies between these four business units – Calvary Robotics, Calvary Advanced Manufacturing, Calvary Global Supply, and Calvary Products – that set it apart from the competition.

The Robotics or Automation unit is the core engine of the company, and the entire business infrastructure was implemented to support this group. Calvary Robotics designs and builds turnkey automation, production, and material handling systems for global leaders in many markets including automotive, medical, consumer goods, electronics, and energy.

Calvary Advanced Manufacturing (CAM) is the ‘build-to-print’ or contract manufacturing component of the company. It works with clients on projects ranging from small sub-assemblies to larger system, product or machine builds that require repetitive manufacturing over longer term multi build contracts. The engineering related to these systems is either provided to, developed or value engineered in collaboration with Calvary.

The third business unit, Calvary Global Supply (CGS), centers on the demand for tooling and fabricated components including spare parts, jigs, and fixtures required by Calvary Robotics and Calvary Advanced Manufacturing for their projects. Additionally, CGS’s equipment, scale, experience and workforce supplies services and tooling to other integrators and original equipment manufacturers (OEMs). The team is also willing to take on mid- to long-term machining and production contracts if that is the desired approach for the customer.

Finally, the Calvary Products division commercializes products and systems utilizing the company’s collective experience and varied skill sets to help a client through the entire project life-cycle, starting with the development and testing of the initial concept and inception phases, through prototyping, alpha- and beta-testing phases, continuing to production and bringing the product to market. Calvary Products provides value-add service and support as part of its offering in order to complete and provide for the entire life cycle management of the program.

Given Calvary’s expertise in all of these aspects of robotics development and automation, clients can expect to save time and money in getting their product into the marketplace while managing risk through the guidance of experts in the field. Calvary believes that its customers’ success is paramount to its own success, and its infrastructure and business units are set up to validate and support this business principle.

Company President Mike Fisher says that Calvary prides itself not only on the composition of the company and Calvary’s business plan but also on its capacity for keeping pace with technological advancement and the dynamic nature of customer strategies and changing core markets.

“We’re part of a very complex and a very reactive industry,” says Fisher. Staying dynamic and ahead of the competition means investing heavily in research and development and continually evaluating the latest enabling technologies. This is done with an eye toward creating disruptive solutions to give customers and their products a competitive advantage in the marketplace, decreased time to market and a higher ROI.

Another key part of Calvary’s business strategy is maintaining strong partnerships with global suppliers of leading-edge products in robotics, vision systems, controls, feeding and material handling technologies, to name a few. Calvary regularly meets with these companies and their management teams to discuss opportunities, challenges and new go-to market strategies. “The robotics and automation industry is very fluid and dynamic, and there’s no place for complacency,” says Fisher, noting that Calvary is committed to staying ahead of the curve.

Calvary believes in deliberate and planned growth rather than growth for growth’s sake. Throughout the history of the company, Calvary has grown consistently by this principle. A large contributor to this comes from having access to the skill sets required to expand into vital areas of the robotics field and thereby attracting the desired customer and technology base needed to maintain and sustain the desired growth curve. Another key factor in the company’s growth has been its ability to provide customers with the most cost-effective and optimum solutions for their challenges.

Calvary has an expert team of more than 250 people spanning every function of the operation, allowing it to provide turnkey, single source solutions to customers. “They say a company is only as good as its employees, and we feel that ours are among the best in the industry,” says Fisher. “This is not only from an experience and a skill standpoint but also from a strong desire to deliver on our commitments.”

The employee base is composed largely of people in skilled trades and engineering. The work environment is highly complex, and there are constant technical challenges due to new product introduction, capacity increases, product changes and new manufacturing processes. These drive diverse skill set requirements and a constant need to do things that have never been done before, all this while operating within tight timelines and budgets. The entire robotics landscape is constantly changing with evolving technologies and customer strategies and Calvary is positioned to capture these opportunities.

To keep up with demand and execute its strategy, Calvary is always on the lookout for new talent. According to Fisher, finding talented people is done by keeping up with the latest technology and building a high-performance workplace culture that exists in a very interesting but demanding and challenging environment. To accompany these aspects of Calvary’s business, are the critical facilities, systems, and processes that are important for the company to remain in control, healthy and profitable while attracting new talent to the team. “It’s always a balance of having the right people in the right places at the right time,” says Fisher.

Calvary’s main focus is on robotics platforms due to their flexibility, scalability, and reliability, but it also has unique forthcoming software initiatives through a different venture company. Robotics software is generally custom written and requires highly skilled people with specialized training, which will or could inhibit a customer’s growth, drive up expenses in terms of capital and support, and increase time to market. The solution is a configurable prompt-based software platform. Using a system like this will greatly reduce costs, time investment and the training and support necessary to operate and maintain robotics systems.

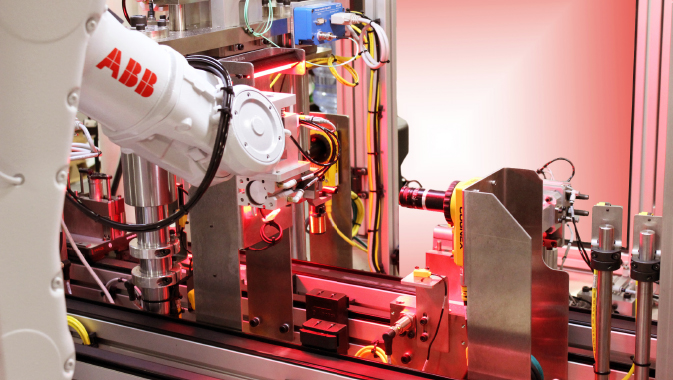

Earlier this year, Calvary displayed some of its robotic platforms, which will eventually use this configurable software control system, at Automate 2017 in Chicago. The X-Cell series of robotic platforms are modular, scalable automated assembly or process systems that incorporate quick-change tooling and material handling configurations. This flexibility allows the platform to accommodate different process and assembly steps that are typical in today’s automation requirements. They also incorporate built-in vision inspection for quality verification as well and vision correction for assembly if required.

These XCell systems are based on both gantry and six-axis robot configurations that can be used for standalone operation or connected for a series of process steps. A key advantage to the customer is that they can be used for process development independent of takt time due to their flexibility and then scaled into production by separating operations into their own cell. This attribute saves valuable time and money, especially in industries such as medical where Line Validation efforts can drive significant cost and time and prohibit getting into the market quickly. Finally, Calvary’s FleX Feed system is a module that uses vision-guided robots for part feeding and sorting. Variable components can be selected, sorted, and oriented from a single feeder. These modular units are connected together in order to build highly reliable and repeatable product assembly and material handling systems.

A forthcoming modular, vision-based robotic production platform design is being finalized which will provide for the ultimate in flexibility, scalability and reliability across a broad range of products and industries. This will further address parts feeding and fixturing as well as provide for more flexible material handling options. This is all in addition to the standard features of the current platform offerings.

Besides being a leader in industry, Calvary is also involved in local charitable endeavors in order to give back to the community and better assist people in need. Last year it raised $40,000 for an organization called Equicenter which is a non-profit that provides therapeutic equestrian activities for people with disabilities, at-risk youth, veterans, and their families. The fundraiser, called Paddles for Saddles, is a paddle tennis tournament to which Calvary employees have donated their time annually for five years running.

Calvary is also a big supporter of AutismUp, which is an organization dedicated to enhancing quality-of-life for people with Autism Spectrum Disorder by providing support and education for people with ASD, their families, and professional service providers. Continuing its support of this organization, Calvary recently welcomed AutismUp to Calvary Corporate Park, its corporate headquarters, where the firm provided new offices for their operation.

As the robotics industry continues to evolve, Calvary is committed to evolving with it. With a heavy focus on research and development, robotics platforms and standards, continuous improvement of systems and processes, and finding the right employees and partners in the industry, the company is positioned to do just that.

Its success and continued growth in the robotics industry makes it a partner that is uniquely qualified to help customers solve difficult challenges in designing, manufacturing, capacity and bringing new products to market. “It’s all about bringing innovative cost solutions to the market, thereby making our customers more productive, efficient and ultimately more profitable,” says Fisher.