Viking Pump works in a wide variety of industries, and it spans the globe with over one hundred authorized distributors in over seventy countries. We spoke to Communications and Marketing Manager Debbie Kleitsch, Product Manager John Hall and Distribution Business Line Vice President John Stillman.

~

There are not many companies that can claim 106 years of service, but Viking Pump can. Since 1911, this pump industry entity has been pioneering technologies that are still used to this day. Its internal gear pump, invented by founder Jens Nielsen, revolutionized the way materials are drawn through pumps, and it is still very relevant.

The internal gear pump is one of the unique aspects of Viking Pump and its products. “It makes us stand out because our founders built this organization on that technology. We have manufactured, engineered and supported it for 106 years. Our founders developed the gear within a gear technology to solve the issue of water in a quarry in Cedar Falls, Iowa and the problem solving culture lives on within the organization,” says Debbie Kleitsch.

Viking Pump has an alloy foundry and an iron foundry in Cedar Falls. A third building houses manufacturing and assembly, and the final facility building is the main headquarters. This level of vertical integration is almost unheard of among pump manufacturers, who mostly outsource components.

The internal gear technology of positive displacement pumps has been adopted by competitors, mostly on “easy” applications like lube oil, where Viking handles almost every liquid. These can handle fluids of virtually any viscosity, whereas most of the pumps in the world are centrifugal and are meant for pumping water. Viking pumps can handle anything from water to peanut butter, plastics or rubber.

“There are a lot of liquids in the industrial space that are high viscosity, and we are really the solution for virtually all of those different industries,” says John Hall.

John Stillman chimes in to talk about the pump, and how that particular technology was designed and developed for entrepreneurs. “We take mother earth, form it, machine it and assemble it. It turns into a pump that is very simple. It has stood the test of time and continues to do so. At the root of it, we are problem solvers.”

I had to know more about the pump and how it would move viscous products such as peanut butter. The rotor that drives the pump has to operate very slowly to get the material into the pump. Then the pump creates cavities where the material flows in. Atmospheric pressure pushes the peanut butter into the pump and fills those cavities which eventually collapse and push the peanut butter out.

Peanut butter is, however, not the thickest material that Viking Pump handles. Silicone caulk, adhesives and polymers are also on that list. There are many imitators that have tried to develop a version of the pump, but Viking Pump is the market leader in this area.

The pump was patented in 1904, and that patent has since run out. However, Viking Pump has many more patents in its name that have changed the pump industry over the last one hundred years.

“We take what Mother Nature has given us – which is atmospheric pressure – and we make it work for our product. We understand the dynamics of our moving components and make it better,” says John Stillman.

The spectrum of products that Viking Pump carries is massive. Due to this, it is difficult to box the company into a specific market. But, generally speaking, it mainly caters to the chemical, petroleum and food industries.

“It’s amazing – as I got involved in this company – how many things are moved or pumped in the world. I believe that pumps are second only to electric motors in technology sold in a year. You are pumping sewage and foodstuffs. All of it has to move in a plant. Until you get involved with it, you don’t recognize it,” says John Stillman.

Viking Pump provides services to well-known companies like Hershey’s, Procter & Gamble, BASF and virtually every oil company imaginable, including ExxonMobil.

To stay relevant, Viking Pump has adapted to what its customers and its customers’ customers want. For example, as more people used liquid detergent in their homes, companies like Procter & Gamble needed pumps capable of moving it. Viking Pump has had to understand market trends and be aware of future client needs.

The research and development department is certainly kept busy. Much of the time, client companies do not inform Viking Pump about upcoming needs. Companies cannot release information that competitors might use because these industries want to be first to the market.

“We have to react fast. Because we own the process from the beginning, we have to be nimble at adapting to those changing needs. We have the foundry here locally; we have a research test lab here in Cedar Falls, so everything can be done here and quite quickly,” says Debbie Kleitsch.

Recently, Viking Pump spent nearly $2 million expanding its newly-renovated, state-of-the-art, 1,600-square-foot research and development (R&D) facility. In total, the company has five thousand square feet of R&D facilities with testing capabilities.

The expansion was necessary because of opportunities like developing a pump for the oil fields of the Bakken Shale Formation. A great deal of testing had to be performed on pumps with much larger horsepower capabilities.

“We have the capabilities of monitoring and developing either a short-term or long-term test to finitely understand the effects of the liquid on the pump. We have twenty different test fluids that are used, of different viscosities, and they represent some of the applications that we support. Our capabilities range from three to three hundred horsepower in testing,” says John Stillman.

Some of it is longevity testing; some of it is to check for potential issues that may arise in the field, or improving new ideas that come out of the engineering department. The engineering department spearheaded a program called ‘Concept to Customer.’ This is when a market trend is noticed and may lead to an idea on how to approach it. The engineers, product managers, and leaders in all departments are very involved with this new development process.

Certain parts of the business require witness testing in which a customer’s quality inspector or engineering team would see the product at work in Viking Pump’s facility and ensure that the testing meets stringent requirements. This is a growing tendency as the company’s global footprint increases. More and more customers will send a crew in to witness the performance of the test before it is shipped.

Part of the focus going forward is on changes in applying marketing techniques to the digital age. Companies are communicating and sharing product information online via such channels as YouTube, and this is becoming more prevalent, even in this industry.

“We are a bit behind the mainstream. We are looking at our tools, our resources and the methods we use to communicate to both our distribution channel and our customers and spend some time adapting and getting up to date on some of these tools. We will continue to pursue that goal,” says Debbie Kleitsch.

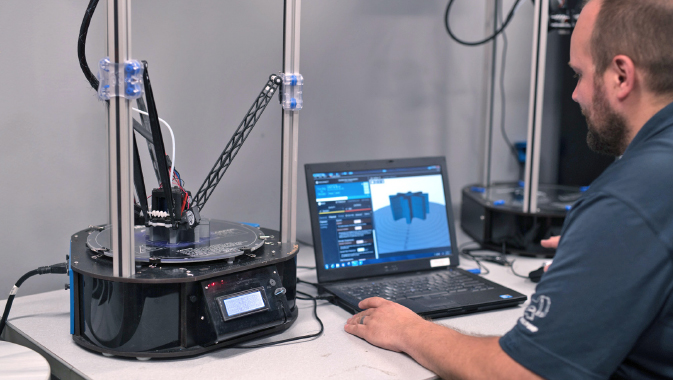

“I would also add, on the R&D side, that we have three 3D printing machines that we are using to prototype new parts to validate the fit and to print the patterns that we can pour metal from,” says John Stillman.

The three-dimensional printing technology has given Viking Pump incredible prototyping speed. A sales engineer can be out in the field, and five days later, that customer will have a prototype product in their hands.

Viking Pump has quite the worldwide presence as its products are found on every continent. The pumps do not require much maintenance and can be in the coldest Antarctic location without needing to be frequently fixed.

Distribution partners are global as well. Business locations are in China and India, but also Canada, Ireland and the U.S. These locations do some assembly as well as manage sales and technical services for these regions.

“We rely on our distribution channels to ensure that everyone around the globe is taken care of. We have distributors in many international countries, and they can be that local response team when a pump does have issues or a new one is needed,” says John Stillman.

There are forty distributors in the U.S. alone, with more than fifty outside the U.S. that can be relied upon for support. There can be complications as economic situations can change quite quickly. There are spurts of success and downward turns, but Viking Pump has great leaders who pay attention to market trends and can adapt.

The recession affected the pump industry, and the drop in the price of oil significantly changed the market, but Viking Pump reacted appropriately. It has seen change many times over one hundred years and knows how to survive.

“We’re cautiously optimistic right now. We are working on many new things that will allow us the growth projections that we want as a group. The future is bright for us,” says Debbie Kleitsch.