For twenty-three years, Inovision has been providing robotic and control systems and software engineering solutions for automation, design, and integration, particularly in the automotive industry. Their work in both retrofit and new projects has earned them a reputable name in process engineering.

~

Malcolm Forbes once noted that the most effective means to creating a strategic vision is through insight. Insight is not merely a one instance occurrence that moves successful companies forward. It needs to be a consistent process approached with an open mind, which in turn, leads to effective decision making and action plans that have the desired outcome.

Innovation is most often the result of such an approach, and this is the premise by which Inovision has operated since their inception in 1992.

Inovision was founded by Principal Engineer Patrick Krawec and President Dave Treadwell, two former controls and software engineers with Dürr Systems. They employ approximately fifty engineers at their corporate headquarters in Chesterfield, Michigan, another office in Rochester Hills, and two satellite offices in Alabama and San Francisco.

There are other companies with a solid engineering base that can integrate robots for a number of industries, but what sets the Inovision name apart from the rest is that “we bring the ability to do research and development or complete custom solutions based on new technology or advanced algorithms,” says Director of Business Development Curtis Goff.

Partnering with companies both large and small, Inovision provides turnkey solutions for the automotive, medical, aerospace and the general industrial markets.

Inovision recently attended Automate 2017, North America’s largest biennial showcase of automation technologies held in Chicago, Illinois and has plans to attend Automate 2019. As an exhibitor, Inovision was exposed to technology-driven companies and realized, “how important that research and development is.” Curtis adds that “it seemed like it really was a differentiator to other robot integrators.”

At Automate 2017, Inovision showcased their newest product: The Fanuc M-710 Robot sander. The sander was created in partnership with Automated Systems & Intelligent Solutions (ASIS) for use in the general industrial and automotive sectors. “We really believe that it is state-of-the-art,” says Curtis. “It’s a total electric robotic orbital sander designed for robotic sanding. In the past, it’s been done with pneumatic manual sanders that have been adapted for robots.”

The sander can have its paper and pads changed automatically. This feature saves time and money by eliminating the tedious task of manual sanding or robot-assisted sanding while improving the overall quality of vehicles.

Inovision recently became a member of the Robotics Industries Association (RIA) which enables the company to align itself with other integrators that are members. The RIA has a demanding certification process, and, once approved, certified robot integration companies demonstrate not only affiliation with an exclusive group but the professionalism, capabilities and competitive edge that membership implies.

The company was responsible for maintaining two experts during the RIA qualification process. The company tested five. “So we’re pretty proud of our engineers that could jump in and demonstrate their robotic ability,” adds Curtis. “The respect for the RIA organization is high. We’re getting exposure to a lot of other markets that we wouldn’t have reached before.”

Inovision makes every effort to understand its customers and become an integral part of their operations. Key customers include multinationals such as Ford, General Motors, Fanuc America Corporation and Dürr Systems Inc. “We’re as much a servicer to them as much as they’re a customer to us,” says Curtis.

“We work on solutions. We work on issues in production, and we understand their design criteria when they go for brownfield retrofit launches or greenfield facilities,” he adds. “We can participate in the simulation work on the front end as well as the assistance with planning so that they come closer to their budgets.”

Customers can then conduct a cost analysis of different suppliers. “By doing that, we think that really gives us an edge when it comes to projects that really fit the target that we’re going after.”

Deciding when a company requires the services of a robotic automated systems and software controls integrator is a question of understanding a need before initiating a system integration project. This need will be as unique as the company itself.

“Some [companies] don’t realize it until they’ve lost their competitive edge,” explains Curtis. It is at this point that such companies will seek different means to grow their margins and will most likely look at, “the ergonomic impact that the work has on their employees and the overall state of how safe the environment is—what they’re doing to the environment. It’s really then that they start to reach out for solutions.”

Adopting a robotic or some type of automation solution can be a real challenge for some companies, particularly those with an engineering department that does not have integration experience. These are the kinds of customers Inovision encounters most. With its experience in creating value stream maps and laying out processes, the company assists customers, “to make really intelligent decisions … We try to come up with good solutions.”

Inovision has well-established open partnerships with both national and international vendors. The company realizes that when it comes to programmable logic controllers (PLC), some customers prefer Siemens and others, Rockwell, for example, and is adaptable to be able to create the package that a customer really wants and needs. The goal is to make a solution that aligns with “what’s their standard, not our standard,” says Curtis.

Inovision’s partnerships with other companies has proven to be beneficial as some of their products will fit any robot or any solution in terms of PLCs. “So it really does put us in a position to be very flexible.”

Inovision aims to empower each employee to, “participate in projects from start to finish,” says Curtis. Meetings are an open forum to discuss all challenges of a project and to communicate any potential risks discovered through its risk analysis process. This is where Inovision’s process maps create value and, “really take projects from the beginning all the way through the company …We’re constantly monitoring that and adapting it to be what we do, not just what we say.”

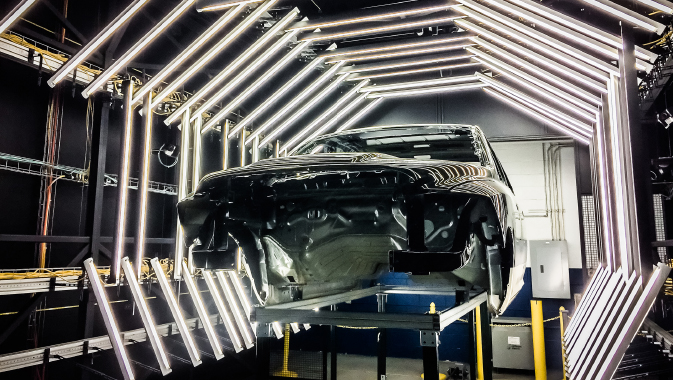

The company’s mainstay is automation in the automotive industry, but even within that sector, “there can be diversity,” Curtis adds. Robotic systems are frequently used in painting and sealing, in the past. “Now we’re moving into porosity inspection and complete vehicle inspection—a lot more vision computation. It really comes back to our core skills in engineering and also in our partnerships for development.”

Inovision’s vision of the future is essentially, “to stay on the cutting edge of the software development and keeping moving software into faster embedded technology and maybe find an innovative partner that’s looking to redo something,” concludes Curtis.