In 2017, Epcon Industrial Systems will celebrate its fortieth anniversary. Having designed, engineered and manufactured and installed over four thousand practical air pollution control technology, heat-finishing equipment and specialty solutions for loyal customers in North America and around the world over the last four decades, it has proudly elevated itself above the competition in both the environmental and metal finishing arenas.

~

Epcon Industrial Systems was founded in 1977 by Aziz Jamaluddin, a mechanical engineer with extensive experience with thermal processing equipment. The company has grown from a one-man entity to a team of professional who share that same depth in experience and knowledge of the industries and the various applications.

Epcon Industrial Systems is headquartered in The Woodlands, Texas, from which it supports its global customers. It operates out of a 250,000-square-foot facility that is equipped with state-of-the-art software and technology that heightens its extensive design, engineering, manufacturing and testing capabilities.

Epcon Industrial Systems’ President and Chief Executive Officer Aziz Jamaluddin says that the secret to success is straightforward: “technical expertise, technical knowledge and providing impeccable service – going the extra mile for the customer. We help them to gain customer confidence and trust in doing business with us.”

Jamaluddin believes that the trust and confidence of customers is important for several reasons. “It’s a personal commitment. It’s the foundation of our culture and the foundation of our values and the foundation of everything that we do. All of our employees are empowered to make decisions to win customer satisfaction and confidence.”

Epcon Industrial Systems acts as a problem solver that always stands behind its work. “The customer has to have the confidence and trust that their problems will be solved by a competent company and group of people. There is no other magic.”

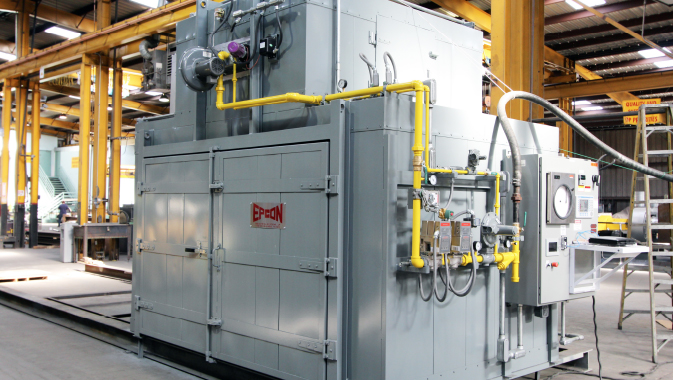

From consultation to design, development, manufacturing, assembly, testing, installation, follow-up service, Epcon Industrial Systems delivers the highest quality systems. The company’s air pollution control thermal oxidizers annihilate VOCs in industrial exhaust through combustion. Customers in many industries use Epcon’s industrial ovens and furnaces to clean or cure products and coatings. Turnkey systems can handle everything from small batches to multi-process, conveyor-belt-fed operations. It also produces lines for washing and industrial paint booths.

“Furnace manufacturers do not normally design and make industrial ovens, or they do not manufacture thermal oxidizers. Our product line is very broad, and this is the industry differentiation and our greatest strength with our uniquely engineered systems,” commented Jamaluddin.

“The nature of the business is, wherever there is pollution, wherever there are VOC [volatile organic compound] control requirements, we reach out to different types of industries,” explained Jamaluddin. Epcon Industrial Systems has clients from a variety of industries, from petrochemical and pharmaceutical to automotive and aerospace and many more, which rely on its patented systems.

Epcon Industrial Systems has repeatedly demonstrated its ability to create customized solutions for its customers, many of which are well-regarded entities such as the government, NASA and large industrial concerns like Ford Motor Company.

“Ford Motor Company changed the process of chemically cleaning the condenser pipes for the air conditioners. They were looking for a new technology because the technology being used at the time for washing was spray washing and dipping and cleaning them with chemical solutions,” said Jamaluddin.

Ford required an alternative approach for de-oiling the aluminum fins used in its air conditioners before the brazing process. These fins are lubricated with oils when they are formed, however, prior to brazing they need to be oil and dirt free. These lubricating oils also contain volatile organic compounds.

The previous method required the use of the chemical tetrachloroethane, a known carcinogen, and it was being banned by the EPA. Epcon Industrial Systems developed a customized solution, a thermal de-oiler for Ford that was far more efficient and resulted in significant costs savings.

“On the chemical cleaning, Ford was spending about $20 million a year in the costs of chemicals and also the disposal cost. After they installed the thermal cleaning system, the cost of natural gas was $108,000 the first and second year. From $20 million to $108,000 is a huge difference and a huge savings to the company,” said Jamaluddin.

Epcon Industrial Systems’ outstanding record of performance is attributable to the investments that have been made in its facilities. By becoming vertically integrated, it had greater capacity to design, manufacture, test and support its products under one roof.

“We have our own manufacturing facility that gives us a great advantage in scheduling jobs and also maintaining quality, rather than sub-contracting this work out where we don’t have as much control in the quality and schedule,” Jamaluddin noted. Customers are even invited to the facility to participate in the in-house testing process.

The company works with its customers long after the sale, which means customer service does not cease once the systems have been shipped and installed. Epcon’s devotion to doing the right thing has helped it retain many loyal, repeat customers.

“Sometimes our employees make very far-reaching commitments to please the customer, and sometimes, financially it could be a little bit painful for us, but we do it because it’s the right thing to do,” said Jamaluddin.

Employees are well-trained and many exceed thirty years of service for the company. As a direct result of their long tenure, Epcon Industrial Systems has the advantage of a deeply rooted knowledge of the products, processes and customer industries as well as technical expertise.

Respect plays a great role in the company’s operations. “We all have great respect – respect for the customer, the employees, and the suppliers. These are all key components of our company.”

Moving forward, addressing workforce needs will be a focus as Epcon looks to pass on the experience of experienced employees the next generation of workers. Just as it is in other industries, there is a concern that a skilled labor shortage could have implications for the company and its ability to sustain growth.

“Growth is always in the works, both in the short term and the long term,” Jamaluddin noted. “The plan is to add talent at all levels to support the growth of the business.”

Jamaluddin appreciates the success thus far but sees far more potential in the market. Acquisitions and diversification could play a role in its growth strategy. Although land costs continue to rise, he has not ruled out the possibility of relocation or expansion.

Regardless of how or where it grows, Epcon Industrial Systems has become the manufacturer of choice for highly-engineered air pollution control technology, heat-processing equipment and specialty solutions.