Jupiter Aluminum is a highly innovative aluminum producer with finishing and painting abilities. Its products are proudly American-made with nearly 100% domestically-sourced scrap. It has discovered a process by which aluminum can be produced in a way that is good for output, the company’s bottom line, the industry and the environment.

~

Jupiter Aluminum was founded in 1992 by Chairman and Chief Executive Officer Dietrich M. Gross, who set out to grow the company into a reputable market provider. With twenty-five years of quality output and exceptional service, he – and the team behind him – certainly achieved that goal.

“The objective, at the time, was to revive a bankrupted company,” said Gross. “Since then, the company grew from two million pounds shipped per month to ten times that volume.” The feat has been achieved through significant investments in equipment, processes and people.

Jupiter Aluminum knows that it may not be the biggest company of its type, but it has proved that you do not always have to be the biggest to have a great impact. While its capacity has grown, its ego has remained small, and it is still driven to offer a personalized level of service and care.

“We bend over backward to please the customer and provide an ad-hoc service level. Being smaller, each customer is de facto important. That respect for every customer has been and still is in the DNA of the company. Being customer-focused has proven to be the right recipe for success,” said President Paul-Henri Chevalier.

“We have strong relationships with the customers, and beyond the sales guy who is going to meet with a buyer; there are technical people along with various managers who can meet with the customers when needed.” Chevalier himself takes the time to meet with customers a minimum of once a year.

Customers operate in the building and construction, government, farming and even the recreational vehicle markets. Recreational vehicles have been a relatively new area of growth for Jupiter Aluminum over the last ten years. Its customer base has grown alongside its increased production capacities and capabilities.

“Growth is not just a factor of capacity available; it is also based on the market vision and the ability to build new equipment so new markets can be opened,” Gross explained.

The company’s market diversity helped insulate it from the impact that the recession had on the building and construction market. It ships over 100,000 tons of aluminum each year, and two-thirds of this volume serves the building and construction sector.

Jupiter Aluminum manufactures a wide range of products. From gutters, downspouts, roofing, trim, soffit coils, window screen frames and vents for the construction market to license plates for the government, irrigation pipes for farming and pipes for fracking, there are many applications for which aluminum is an ideal material.

The company is headquartered in Des Plaines, Illinois; its aluminum operations are located in Hammond, Indiana where it is one of the largest employers; its coil coating division is in Fairland, Indiana, and it also has another painting facility in Beech Bottom, West Virginia.

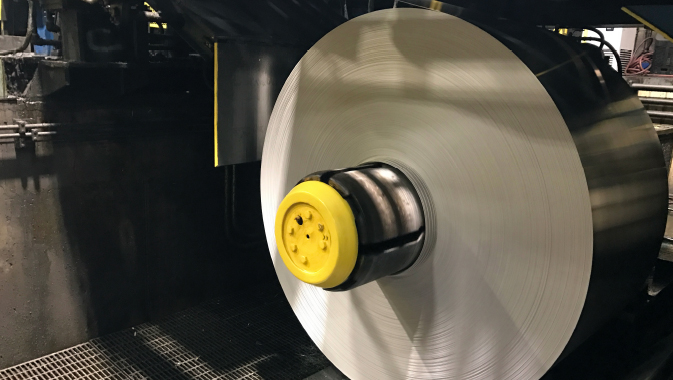

In Hammond, Jupiter Aluminum boasts twenty-five acres of land and a 600,000-square-foot facility equipped for melting, casting, cold rolling, annealing and finishing operations. In late 2004, the company invested in a new continuous casting machine which significantly added to its output volume. The other facilities are equipped for painting and finishing.

Gross’s vision has always been very forward-thinking, whether it was an awareness of the challenges associated with rising fuel costs or the need to mitigate the environmental damage that inherently resulted from the operation of its furnaces.

With those considerations in mind, investments were made in developing an oxy-fuel combustion technology, which uses pure oxygen in the furnaces instead of air to support the combustion in the company’s natural gas powered furnaces. This results in higher temperatures while consuming less fuel when compared to traditional methods. Jupiter Aluminum saw reductions in its natural gas use by an average of seventy percent.

“The money invested in [research and development] was very significant, and the results were great payback with natural gas savings, and you pay it forward with the environment as well,” said Chevalier. “Not only does the technology saves a significant amount of natural gas, it also cuts dramatically the CO2 emissions by nearly 70% and reduces to nearly nothing Nox and Sox emissions. While these environmental benefits are not necessarily recognized by the customers, they allow Jupiter to be extremely clean,” he explained.

“Regulations are pretty stringent in the U.S., and that’s a good thing. Respecting the environment is critical as we don’t inherit the earth, we borrow it from our children. That old saying has never been so true,” he continued.

From that oxy-fuel perspective, Jupiter Aluminum exceeds industry regulations. The technology was commercialized in 1997 and patented by its sister company Jupiter Oxygen Corporation.

Quality is another focus of Jupiter Aluminum. Great efforts are made to ensure customers receive products that are produced by the highest standards of quality. The same approach has been taken with safety, according to Chevalier. “Safety is a mindset,” like quality, and every employee is trained with that approach in mind.

“On-time deliveries are critical to the success of the company as well. Over the years, efforts have been made to extend the quality product to a quality service. While not perfect yet, the improvements are visible. These are tangible things, to have a quality product delivered on time, but that’s not enough. All the intangibles: the relationships, the depth of the partnership also considerably helped us succeed over the years,” Chevalier said.

The goal is to establish long-lasting relationships with the customers, the suppliers, the vendors and of course the employees. And, despite the advancements in technology, for Chevalier, nothing replaces face-to-face interactions when it comes to satisfying the human component of these relationships.

Jupiter Aluminum’s commitment to its employees is evident in how the company overcame times of adversity. At the end of 2006, a large fire forced the company to shut down operations for months, and its response was quite surprising.

Despite being shut down, “we kept paying our employees. We thought we had to do it; we wanted to do it. It was a way of not just thanking them and keeping them – they would have had no jobs otherwise,” says Gross. It has paid off impressively.

“When we restarted ten months later, all those people were working even harder to make sure the company took off again. That’s how it works; first you show them, help them, support them, and then the employees will give it back to you.”

Jupiter Aluminum is also a crusader for the industry, having taken an active role at the policy level, meeting with the government and relevant industry bodies to fight against illegal dumping of aluminum by countries like China.

This activity is having a negative impact on the market and domestic manufacturing in the U.S. in particular, where in the last twenty to twenty-five years, upwards of twenty smelters have been forced to shutter operations. With those closures go hundreds, even thousands, of well-paying jobs for Americans.

In September 2016, Jupiter Aluminum was present before the International Trade Commission to advocate for fairness in the market. “If we lose the American Dream for people, it will be a catastrophe,” said Chevalier. The US government has launched an investigation into the aluminum industry which Chevalier hopes will help level the playing field.

“We believe in competition because it makes you smarter; it forces you to innovate; it forces you to be better with customers, with your suppliers and with everyone. Competition is good, but competition has to be fair,” said Chevalier. Fairness is what he hopes will result from these proceedings.

In the meantime, Chevalier anticipates the return of the housing market but also hopes home ownership will eventually become accessible to all. “It’s a challenge. We have to find a way to resume making the American Dream – which is to own a house – more accessible to the new generation.” This would drive growth and profitability for everyone in the supply chain.

More than profitability, Jupiter Aluminum cares about the relationships that underlie the company’s continuing success and ability to deliver results. “To me, what’s important as we celebrate twenty-five years, is to thank the suppliers, the vendors, the employees, and our customers – everyone,” said Chevalier.