When it comes to precise and dependable pressure sensing instrumentation, GP:50 NY Ltd. is one of the world’s leading suppliers and a highly recognized and respected name. Each day, customers from many industries rely on its products, most of which are customized to address unique needs and requirements.

~

GP:50 NY Ltd. was founded in 1986 by mechanical engineer Donald J. Less. Located in Grand Island, New York, the company was built upon Less’ quarter of a century of experience in the pressure instrumentation field.

“GP:50 started in what’s called the melt pressure market or plastic injection molding and then branched out into other markets. About ten years into the business, GP:50 pursued the aerospace market, which is now one of our largest market segments,” explained Bob Atwood, Vice President of Sales and Marketing.

“About eight years ago, we began to pursue the upstream oil and gas market, which grew very rapidly and for many years was the largest or second largest portion of our business. The timing was right then as the oil market was doing well, and many of our competitors were having delivery or product issues.”

Over the last several years, GP:50 NY Ltd. has placed great emphasis on improving product accuracy to take advantage of market opportunities. In doing so, it has entered what is referred to as the test market, which typically involves automotive testing. This now represents the third-largest – and still growing – business segment for the company.

“Our more recent product developments have focused on higher accuracy products for the test and aerospace markets, as well as products that can survive the high shock and vibe levels for space flight, military aircraft and miniature products to save weight and space on flight applications,” Atwood explained.

GP:50 NY Ltd. is also developing products that can withstand higher temperatures, as well as low-range cryogenic-rated products. Its products can currently endure 400 degrees Fahrenheit. Atwood indicated that it is the mission critical applications in space flight or subsea applications that are the most challenging, though these significantly advance innovation.

“They can push the limits of your technology at times, but this push has created new product lines for us. There have been times that solving an application issue has generated a full product line for us.”

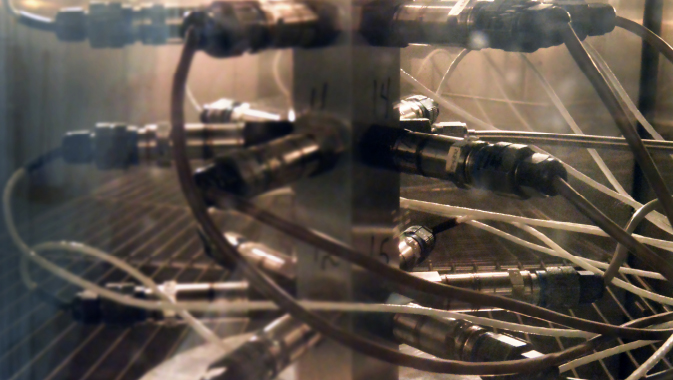

GP:50 NY Ltd. serves customers in the aerospace, oil and gas and petrochemical, industrial, medical equipment, sanitary, hydraulic and pneumatic control, water and wastewater industries across North America, China and Europe with its extreme and high temperature, low-cost and submersible products.

“We are very application driven, meaning we don’t typically sell off the shelf products. We listen to the customer’s need and either design a product that meets this or with thirty years of product history, have something we’ve designed that fits that need,” said Atwood.

“We pride ourselves on providing excellent customer service and respond to our customer requests typically within a couple of hours and no more than twenty-four hours. We develop and spec products to fit an application and not force the application to fit a product.” This approach has served as an important difference for GP:50 NY Ltd.

An example of this customization in action is the work that was recently completed for a customer’s fracking application in the upstream oil and gas sector. The customer was experiencing repeated product failures using a competing off-the-shelf product and approached GP:50 NY Ltd. for a better solution.

“We were able to design a new unit just for that application, and it’s lasted years for them now and not weeks as was the other brand. That single application turned into a very large product for us and has since been used at every major well servicing company in the U.S. Of course, shortly after, our competitors copied it, but we still own market share,” noted Atwood.

For GP:50 NY Ltd., the emphasis is on customer service and delivering application-specific results when customers need them the most. Quick response times and the demonstrated ability to provide innovative solutions that are both accurate and unfailing has been the key to its continued success over the past three decades.

GP:50 NY Ltd. is ISO 9001 certified and registered with International Traffic in Arms Regulations (ITAR). These standards help to provide a structure by which continuous improvement and training can be used to produce exceptional output for its customers.

Production operations at GP:50 NY Ltd. are organized into product specific groups: an aerospace group, an oil and gas group and a test market product group. This ensures the necessary employee expertise is well deployed and helps employees to become product experts. For example, its aerospace group is trained in NASA’s soldering and assembly techniques and standards.

“There is much skill involved in building many of our products. Some processes can take months before an employee is skilled in that process. Having a highly-trained and motivated workforce allows us to continue to grow,” Atwood said.

Knowing that employees are its greatest asset and acknowledging their value, no employees were laid off when oil prices were down and times were tough. This preserved the talent and expertise the company had worked so hard to gain.

“We were able to shift them around to other areas within the company. We weathered that downturn very well, and it has since begun to recover, providing us with a quick response to this turnaround. Losing highly-trained employees during a downturn hinders your recovery when the market returns, and we didn’t experience this skill loss when the oil prices returned,” Atwood said.

GP:50 NY Ltd.’s family-oriented culture binds every layer of the company. Employees enjoy the benefits of an open-door policy and a positive environment in which to work, and this results in a low turnover rate and good productivity. In fact, there are employees who have been with the company since its inception.

Atwood shared a small example of the culture at GP:50 NY Ltd. that proves great results for its employees. “When the company started over thirty years ago, the owner brought in donuts every Friday and continues to do so now with over 115 employees.”

In addition to its employees, another element of GP:50 NY Ltd.’s success has been its relationship with Blue Ribbon. Blue Ribbon brings its own brand of products, knowledge, experience and manufacturing facility to produce high-quality, competitively priced products for its customers.

As an affiliate, Blue Ribbon offers products for water treatment applications, serving as a direct distributor for original equipment manufacturers. Its products include pressure and level transducers, industrial pressure gauges, industry grade thermometers, pump controllers, diaphragm seals and accessories.

“About eight years ago, the opportunity to purchase Blue Ribbon Corp. arose. We had been private labeling their patented Bird Cage product, and the owner wanted to retire. They were solely focused on the water treatment market and had a good name in that market. This helped GP:50’s entry into this water treatment market and continues to grow well.”

GP:50 NY Ltd. continues to identify ways to serve its key markets. Product development and reducing lead times remain a focus, and as applications change, so too will its products to better address those evolving needs.

GP:50 NY Ltd. is proud of the fact that its products are made in the U.S. and that it continues to serve a vital role in its customers’ applications around the world.