iAutomation is a distributor of industrial automation products. However, over the course of its history, the company has developed an expertise that has enabled it to form mutually beneficial partnerships with clients far beyond the typical distributor relationship. “Our mission is to partner with customers and suppliers,” says iAutomation Marketing Director Josh Walters, “and to help enable innovation within their business because when they grow, we grow.”

~

iAutomation has the ability to connect clients with equipment that best suits their specific needs through a carefully selected network of industry leading suppliers, but this is only the beginning of the value that it brings to the table.

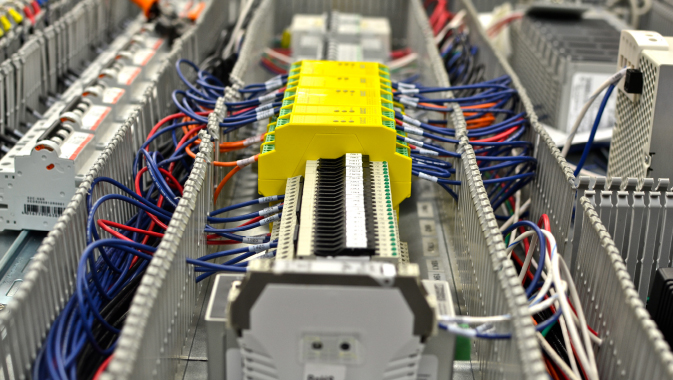

The company has an expert engineering team committed to providing innovative solutions to any challenge a client can bring. The engineering team’s capabilities and production services help clients utilize iAutomation products successfully in their automation systems, allowing customers to focus on their core competencies, improving their operational efficiency and extending their resources. The team delivers “plug-and-play” solutions to customers, which eliminates implementation risk and enables successful connections between customer equipment and third party developers.

The company’s dedicated services help customers increase their speed to market while remaining cost-effective. These services include application software development, custom assemblies, custom cabling, panel building, inspection and testing, customer training and more. The iAutomation team is equipped to help clients through every stage of a project in ways that far exceed what is generally expected of a distributor.

iAutomation takes a different approach by stepping into the role of a trusted adviser and helping the customer make the right equipment and component selections for their operation. If a piece of equipment needs a new sensor, for example, an iAutomation engineer will take a careful look at the existing system and help the client find a sensor that will integrate properly with it and the rest of the machine. It is through the expertise and innovative spirit of iAutomation engineers that the company is driven upward.

The iAutomation brand was born in 2010 out of the joining of two successful automation companies from the East Coast of the United States: Automation Solutions of Beverly, Massachusetts and Integrated Motion of Greensboro, North Carolina. Each was a successful and rising company on its own, and the two shared a specialization in mechatronics and motion control systems. Between 1997 and 2001, both companies, being only peripherally aware of each other at the time, began to address some unmet industry needs in the automation space by supporting new technologies and forming partnerships with suppliers that were driving the leading edge forward.

In 2003, the two companies began to focus on the ability to provide complete machine control solutions – systems, rather than just components – and partnered with a company called B&R Industrial Automation, which was and still is a leader in the field of machine control. “Customers today are looking for integrated solutions,” explains Walters. “We saw this. The market was moving toward integrated/system solutions,” and as such, this partnership enabled customers to focus on their core business, while enhancing the performance of their machines and remaining competitive in the global market.

“We had Automation Solutions and Integrated Motion,” says Walters, “two very similar companies – one in the north and one in the south – doing similar things. So in 2007, we merged them together to form what is now iAutomation.”

By bringing the two firms under one brand, iAutomation was able to consolidate a lot of engineering power and expertise, doubling the size of its team while expanding its capabilities and serving a wider geographical region. In 2011, the company acquired Action Automation, the Northeast’s premier pneumatic technology distributor, with manufacturing and assembly capabilities. This acquisition was strategic in that it further expanded iAutomation’s offering with complementary products, services, skills, and resources. The foundation of iAutomation has resulted in significant value to customers through a complete machine control solution. The addition of Action Automation’s strengths in pneumatics and other related components and integrated services only serve to enhance this overall value.

“We are now able to provide a better offering through these strategic acquisitions,” says Walters. “We want to support every area of technology as it relates to the factory floor. We maintain a small company mentality while doing it on a large scale.”

This acquisition expanded the size and the function of the company dramatically, and by 2013, the leadership began retooling the business model to focus on achievable growth initiatives. Charles Williams, who was the president of Integrated Motion, became chief executive officer of iAutomation, and under his direction, the company underwent a very strategic transformation by fine-tuning its supplier network in support of the vision for the future of the company. The company seeks out suppliers that are focused on continuous investment in innovative technology and are forward looking.

Through this effort toward strategic growth, the company acquired another like distributor, Piedmont Automation, which had a heavy focus on a systems approach. This acquisition extended iAutomation’s market into Georgia and Florida, adding more engineering talent and industry experience.

Today, the company employs 160 people including 75 degreed engineers. “Where we’re really differentiated is in the kind of company we are,” says Walters. “We’re not selling commodities out of a catalog. We’re really getting in there to understand the philosophy behind the machines and the companies that we’re working with and helping them innovate for the future.”

This push to help clients grow is fundamental to the iAutomation model. There is a culture of innovation within the company, and it tries to bring that culture into all partnerships to achieve a special solution for every customer. This creates market share for the customer and, in turn, creates market share for iAutomation. Innovating for the future is the aim of every project.

The goal is to build the most efficient and profitable system for the client to secure a lasting partnership and to further the company’s reputation in the industry, but the road to that end can be a challenge. If the company can control the brain of the system, it is then best positioned to improve its overall performance. Though, for the customer, swapping an existing control system for something new is a huge endeavor that can often require retraining of staff. It is a big step to make that kind of change, but when a client puts enough trust in iAutomation, the result is always a better performing system and a more profitable operation.

Efficiency and productivity are cornerstones of iAutomation. This is reflected in every aspect of the work the company does and in the way that it is run. As it has changed over the course of its history, the systems used to manage the operation of the company have changed along with it.

After merging Automation Solutions and Integrated Motion into iAutomation in 2007, the company standardized its enterprise resource planning (ERP) and customer relationship management (CRM) systems with NetSuite’s cloud-based applications. Prior to 2004, these critical components of the business were managed through separate systems, leading to a disconnect that could slow the overall operation of the company. In 2011, iAutomation acquired Action Automation and Controls and replaced its 18 in-house servers and on-premise ERP system with the NetSuite cloud applications used by the company’s other facilities. iAutomation’s move to a unified cloud environment for ERP and CRM helped drive double-digit revenue gains and improve customer service.

In 2004, the company began a major transformation that allowed it to integrate these two systems into one consolidated platform, growing with the platform and integrating acquisitions into it. This new system connects every department, giving everyone real-time access to any information they might need from finance, inventory, quotes, order taking and customer relationship history. Everything is in the cloud which gives the team access from anywhere at any time.

“We knew things were changing,” says Walters. “We looked into the future and realized that this was going to be the best thing for us going forward. It was a big change.”

Throughout the history of the company, it has bettered itself by continually refining its processes and investing in training and technology so its people can carry iAutomation to further success going forward. The company is always seeking better solutions to meet customer expectations with a focus on structuring itself to bring the best technological resources into every project. The company understands that it depends on its people, and it makes great effort to foster an environment where employees are driven to achieve and feel invested in the company’s overall success.

‘iNSPIRE’ is an internal program that allows any employee to acknowledge the efforts of any other. Workers can fill out inspire forms to recognize things that someone might do to help a peer or to improve the company in some way. “We want people to acknowledge each other,” says Walters. “It’s a good way to shed light on things that often go unnoticed. We don’t want anything to go unnoticed.” The company is committed to building a comfortable work environment for its people, and its people, in return, are committed to the company.

iAutomation has worked tirelessly to become a company unlike any competitor. It is a distributor at its core but with an unmatched technology offering, a vast amount of engineering talent, supporting services and a unique approach that truly makes it different.