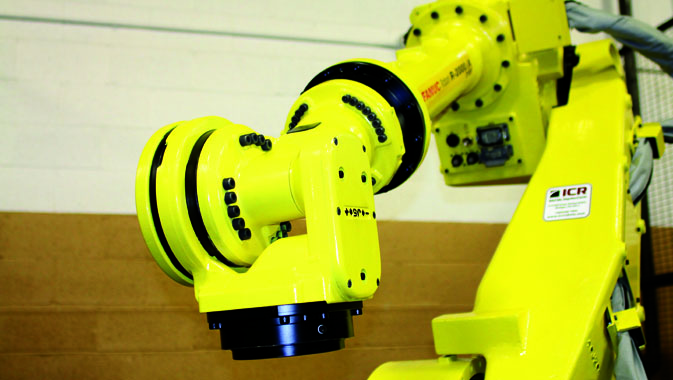

Over the past twenty years, Michigan-based ICR has grown from a repair facility to a global full-service solution provider. The company works with customers worldwide on electronic and mechanical repairs for manufacturing facilities. It also specializes in asset management, automation equipment sales, robot sales, robot refurbishing, integration, decommissioning, field service and machinery sales.

~

From humble beginnings as a two-man operation in a 1,400 square-foot space, ICR has today grown to three buildings in the United States totaling over 100,000 square feet and has 175 staff at its U.S. operations alone. Built modestly as a two-man operation in a 1,400 square-foot space, ICR has become a recognized leader.

Before the business was created in 1992, Vice President Glenn Dantes and President and founder Paul Gutierrez – both trained electronics service technicians – were working for Pertron, a resistance welding company. Gutierrez was a manager of the repair and service department, and Dantes was a service technician. When Pertron was sold to Square D, the well-known American- based manufacturer of electrical equipment, Gutierrez was authorized by Square D to repair older, obsolete weld controls and Industrial Control Repair was born, with Dantes joining as partner in 1993.

Soon, the duo did everything from repairs and field service to sales and shipping. ICR soon found itself being asked by customers about repairing other items and so the company purchased or built testing equipment and the machinery necessary to meet growing client demands. Still known to many of its clients as Industrial Control Repair, the company realized that as it expanded and began developing other services and products, it needed a rebranding. It recently became ICR Services to better suit its service offerings.

“Since our goal is to provide solutions for our customers we’ve invested in creating synergistic business units,” says VP Dantes, “and those business units fall into three categories: Repair, Products and Services,” he explains.

“When working with customers, we want them to be able to come to us and to be able to provide solutions for them. That has really grown our business,” states Dantes who, like Gutierrez, gained valuable experience in both the service and repair side while working as an electronics technician.

“Coming from the service business and the repair business, we acquired good perspectives about what customers were looking for,” he says. “We were in the plants; we weren’t just a couple of business majors who just went out and hired a bunch of people. We were working closely with maintenance people and engineers and got a very good understanding of customers and what they were looking for, and I think this gives us an advantage over some of our competitors.”

This understanding has made ICR a company of choice for its growing client base. Just a few of the brands serviced by the company include Fanuc, Allen Bradley, ABB, Siemens, Indramat, Yaskawa and Nachi.

From its beginnings in repairing obsolete Pertron and Square D weld controls, the company has grown to provide a range of repair services in electronics, robotics, CNC machines and mechanical. ICR is also a leader in OEM repair authorizations. It is ISO certified (Quality Management System ISO9001:2008 standard for Sales, Repair and Services of Industrial Electrical and Mechanical Equipment). It also practices lean manufacturing processes, which help lower costs through gained efficiencies, allowing ICR to provide very attractive repair prices.

ICR is equipped to handle every facility service from preventative maintenance to asset management, breakdown assistance, repair process coordination, robot integration, field service, engineering and decommissioning. The company provides surplus parts for its automation equipment sales and machinery sales of larger items such as presses and CNC machines. For customers interested in purchasing a product, ICR’s online store carries a superior range of machinery, robotics – new and used, controls, mechanical products and welders. By operating through these business units, ICR can meet needs of all customers while remaining as cost-effective as possible.

Under asset management, the company often works in larger companies, such as Toyota, Chrylser, Ford and Honda, with one plant employee managing the repairable assets, barcoding, tracking and sending out or receiving items for repair.

On the product side, the company is proud to provide customers with a range of quality remanufactured products at a fraction of the price of purchasing new. Products fully refurbished by ICR’s trained team carry a one-year, in-service warranty.

ICR’s Machinery Sales group sells used and reconditioned machinery as well as plant support equipment which goes hand-in-hand with decommissioning. During the decommissioning of a line or plant, there are often opportunities to buy used, surplus and excess equipment that can be resold. “Because of our knowledge of robotics and machinery, we look for equipment that we can repurpose or resell,” says Dantes. ICR looks at all opportunities to buy stamping presses, CNC machines, gear cutting and injection molding machines.

ICR can provide global decommissioning solutions and its skilled staff works closely with the customer’s workforce to ensure the project is completed safely and with minimal disruptions in operations. ICR looks for long term business partnerships wherever possible and maximizes its offer with that in mind. “We want it to be a win win project for both ICR and the customer and that’s what will drive the growth and relationship,” says Dantes.

The company’s integration department provides cost effective solutions for automation. “With in-house engineering and fabrication we can design a turn-key system that meets or exceeds the customer’s expectations,” says Dantes. ICR often times will utilize its large inventory of refurbished robots, positioners, machinery, surplus parts, circuit boards and servomotors in its systems to help keep the cost down. The team will also provide installation, training and after sale support insuring complete customer satisfaction. With ICR being an authorized robot integrator for Yaskawa/Motoman and Nachi, the company can provide a new robot option as well.

Initially, ICR’s robot group purchased robots then refurbished and sold them. Customers then asked the company if it could do more, including programming robots and integrating them into automation systems. This in turn led to additional solutions for customers, including after-hours services and spare parts.

ICR has grown to its present size with very little marketing, although it has recently hired a marketing professional. To date, most of the company’s business has been through word of mouth referrals from satisfied clients. It complements this with about fourteen salespersons who look for opportunities and attend trade shows, and an established web presence.

The company has a blue-chip client list including manufacturing giants like Toyota, Ford, Cummins, Chrysler, Honda and General Electric. For its many prominent customers, ICR can determine client needs and supply those from its locations in the U.S., Canada, Mexico and South Africa.

Although automotive has been a large part of ICR’s business to date, the company has seen extremely rapid growth in wind turbines, with many needing electronic repair. “Many of these wind turbines are dated – requiring constant repairs – and that business is growing quickly for us,” says Dantes.

The company has been very active in the food and beverage industry and the appliance sector, working for well-known businesses such as General Electric, Whirlpool, Con-Agra, and Better Made, to name a few. “We are extremely diversified, and we are constantly expanding and looking for opportunities outside automotive, as the automotive industry is very cyclical.”

The company aggressively pursues original equipment manufacturer (OEM) authorization, such as it has with Square D. ICR approaches OEMs to service facilities, as some OEMs are based overseas and do not have a solid service presence in the United States. “We definitely look highly on becoming OEM-authorized,” states Dantes. “It goes a long way when you can go into a plant and do a presentation, say you are authorized and go down the list of major corporations that you are authorized by.” Some of the company’s authorizations include Nachi, Kawasaki, Lincoln, Panasonic, Yaskawa and Miller, to name a few.

Experienced and flexible when working with customers, ICR is exceptionally skilled when it comes to dealing with businesses entering automation for the first time. Many new businesses are unsure of what may be required or of the costs of new robots versus refurbished models – which varies widely. Award-winning ICR does not sell itself as the least expensive, but instead promotes the value of its services. “We don’t market ourselves as being the lowest-cost supplier although many times we are; we market ourselves as being the number one supplier from a quality and support perspective,” says Dantes.

The company’s engineering group tests products under real-world conditions and has extended its abilities to thoroughly test equipment at all its sites. “It is very important for us to have one repair standard,” comments Dantes. “The same parts will be used, so it is one repair process, and we take that very seriously. We want the best possible repair for our customers, and to do that, we want one repair process. So any technician can look at a documented procedure for a tester and know how to do that repair.”

ICR is growing in the United States and through its satellite locations as it continues to diversify its products and services and become a global supplier. “In the next two years, with our engineering department really expanding, our customers want engineered solutions.” Engineering, he says, is going to become a significant part of the company’s growth. “We don’t just repair, service or sell one product: we do a lot of things.”