Select Tool, Inc. of Oldcastle, Ontario designs and manufactures fixtures, gauges, and related products, primarily for the automotive sector and offers automation solutions as well. The firm is undergoing rapid growth and is looking to expand its operations into Mexico. Select Tool takes pride in being vertically integrated and capable of handling all stages of a project from design through to machining, assembly and beyond.

~

Based in Southern Ontario’s automotive epicentre, Select Tool, Inc. currently occupies three facilities totalling 80,000 square feet.

“Plant 1 houses corporate offices, our engineering department and assembly. Here we assemble and certify our check fixtures. We also assemble and validate our automated systems,” says Vice President and Co-Owner Dave Tomassi.

At 45,000 square feet, Plant 1 offers a coordinate measuring machine (CCM) certification room with eight CMM machines and three portable CMM arms, a computer numerical control (CNC) lathe department and a full electrical department for machine wiring and electrical panel/enclosure build. A CMM is used to measure the physical characteristics of objects.

Plant 1 also has design capabilities for programmable logic controller (PLC)/controls programming, electrical/pneumatic schematics, fixtures, specialty tooling, robot simulation, automation and vibration/stress analysis.

“Plant 2 (25,000 square feet) is our advanced manufacturing division. This facility also has offices for program management and sales,” continues Tomassi.

Plant 2, at 25,000 square feet, features sixteen CNC machining centers, a full fabrication department that can fabricate fixture bases, machine sub-components, machine frames and other items as well as facilities for waterjet and plasma cutting. Automated palletized loading systems are utilized in this plant so that critical equipment can be run continuously.

At 10,000 square feet, Plant 3 offers extra assembly space for smaller-scale automation jobs and specialty tooling.

Select Tool is currently in the process of setting up a branch in Querétaro, Mexico. “This facility will manufacture the same products as our Oldcastle facilities and will provide full services. The size of this facility will be approximately 16,000 square feet,” says Tomassi. The facility is expected to be operational by this October.

He explains the motivation behind the move to set up in the south. “Over the last five years, more and more of our product has been delivered to Mexico. Although it’s being sourced from the Detroit area, the final destination of the product has been Mexico. A couple years ago, we found out some local mould shops were starting to move there to set up satellite facilities. We were also aware that a couple competitors of ours had already moved down there. All that, in combination with customer demand, prompted the decision [to establish a Mexican branch].”

While Select Tool does do work for consumer, recreational and heavy industrial markets, ninety percent of its business is automotive-related. “We supply to numerous automotive OEM’s as well as many tier one and tier two suppliers. We supply product to all of North America, South America, and Europe,” states Tomassi.

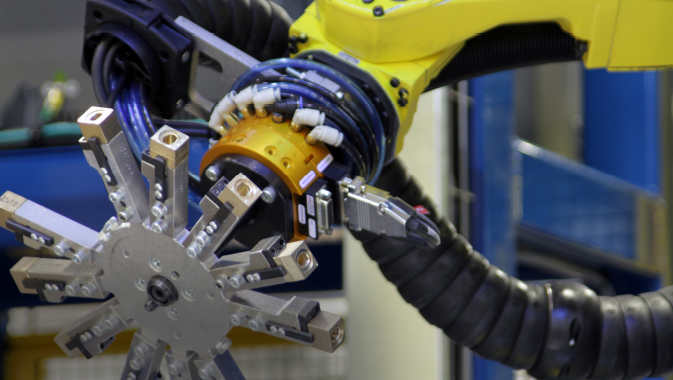

The company’s quality assurance fixtures division makes work holding jigs, holding stands, CMM holding fixtures, and more, while an automation division can put together end-of-arm robotic tooling, index machines, material handling, pallet and conveyor systems. Select also offers a wide range of services, from CNC machining to inspection, fabrication, controls and electrical work, and design.

The company does robotic systems integration. While it installs robots from most large manufacturers, the majority of robotic systems it handles are made by FANUC.

“The breadth of these services is a representation of our vertical integration,” says Tomassi. “Our CMM department is considered one of the largest in North America.”

Tomassi cites the company’s size – it has over two hundred personnel – strong engineering and manufacturing capabilities and a high-level of investment in technology and facilities as factors that make it unique. The company can “handle work that other competitors simply cannot complete, or complete effectively,” he states.

For a booming firm, Select’s roots are rather humble. The company was founded in 1996 by four partners, including Tomassi. Tomassi and another founding partner, Paul Hollister, are the current owners.

“We started in a modest two-thousand-square-foot facility with the four partners and two employees. Early struggles included trying to convince tier one and two customers to give us a chance to do their work,” recalls Tomassi.

At first, Select largely served as a sub-supplier to local firms. “We would look for pretty much anything, although we eventually wanted to be known as a gauge and fixture shop. One of our customers, in the beginning, went out of business and almost forced us to close as well,” states Tomassi.

“Work did eventually develop a small customer base, but slowly. It was very difficult to attract experienced employees for these same reasons. Any money that was made had to be reinvested in the company, and we went for approximately three years without really paying ourselves. These issues made us realize that we needed to move into our own facility. As a result, we moved into a new 12,000-square-foot facility in late 1998. This gave us a new face, but the struggles to gain enough work and profit still were present. All these factors motivated us to be very cost competitive [and offer] uncompromising quality and value to try to grow our customer base,” he continues.

That goal was achieved, and Select embarked on a lengthy growth spurt. Ironically, this growth spurt came in part because of the 2008 to 2009 economic downturn. Unlike many other firms in the region, Select Tool weathered the recession reasonably well. This left the company in a strong position, as competitors in the U.S. and Canada went out of business. Select then began experiencing rapid growth, in terms of both sales and personnel.

Two other developments, both of which took place roughly three years ago, added further momentum to Select’s upwards trajectory. The firm decided to diversify into automation and build a new, 45,000-square-foot facility. Building the latter demonstrated to customers that the company had confidence in itself and was committed to growing, says Tomassi.

“We had twenty-eight employees in 2009 and now have over two hundred,” he notes, proudly.

Because of the varied jobs and roles at the company, new hires range from high school graduates to people with advanced university degrees.

“The important things we look for are people that are smart, have a good head on their shoulders, and have a willingness to work hard and succeed. We encourage rapid growth and development of all our people to mirror the pace and growth of the company,” says Tomassi. The company invests in apprenticeship programs and regular employee training, he adds.

“We feel it is important that employees want to come to work every day,” Tomassi describes of Select Tool’s corporate culture. “As a result, we have never believed in over-managing or stringently overseeing our people. This can be both a good and bad thing. Employees that have natural self-discipline tend to do best. We attempt to break down barriers between owners, managers, and employees to give everyone a sense of comfort and casualness which we find promotes excellent communication and camaraderie.”

Challenges facing Select Tool include dealing with the workload and lengthy payment terms in the automotive sector. Taking on more work means finding additional, qualified workers. This can be difficult, given the current skilled labour shortage in North America and the fierce competition for talented workers in Southern Ontario’s manufacturing hub. Payment terms from automotive companies, meanwhile, can sometimes extend up to twelve months.

Select Tool is NSF ISO 9001:2008 certified and has a quality manager to ensure standards are kept. This is then reviewed by an external auditor.

“The extent of our vertical integration is such that we can control quality and timing,” says Tomassi. Likewise, there is safety training for personnel including in the proper use of equipment, proper storage of equipment, and a sense that safety is everyone’s responsibility. The company also has a safety director.

Suppliers tend to be locally based. The desire for proximity is understandable given the company prizes timing in addition to cost and quality in its outside suppliers.

Select has a multi-faceted promotional strategy. “We have a social media presence on Twitter, Facebook, and LinkedIn. These mediums are largely used to reach prospective talent. We exhibit at a select few trade shows and summits each year to reach new prospects and increase our exposure to different industries (i.e. other than automotive). We do not advertise very much. Most of our marketing efforts are direct or face-to-face given the B2B [business-to-business] nature of our industry,” says Jessica O’Kane, who works in Marketing & Business Development.

Tomassi’s forecast for the next five years is a blend of optimism dashed with a dose of economic realism. “Nobody knows when the shoe’s going to drop and [if] the automotive industry’s going to go into a slump again. We still kind of remember 2008 to 2009 pretty well,” he states.

For all that, “I think in five years, obviously, we’ll have a bigger presence in Mexico. We will have manufacturing operations to supplant our existing sales office in Querétaro, Mexico by the end of 2017. We have also contemplated having a facility in the Southern U.S. A lot of our customers are based down there,” says Tomassi.