Javelin Technologies Inc. is a Canadian expert in 3D designs. The value-added reseller has assisted thousands of manufacturing and engineering companies across Canada with product data management, electrical and mechanical design software, 3D printers and related training.

~

Javelin Technologies has been dedicated to supplying the best design and manufacturing software services and solutions since 1997 when it received its SolidWorks certification demonstrating its proficiency with SolidWorks 3D solid modeling software. It didn’t take long for the company to establish itself in the industry, becoming the fastest growing SolidWorks reseller in Canada in 1998. Major accounts were brought in over the next few years with companies such as tire manufacturer Michelin, electronics manufacturer Celestica and multinational engineering conglomerate Siemens.

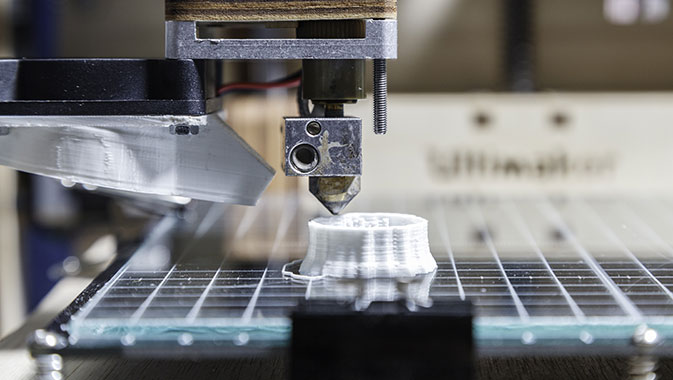

Also known as additive manufacturing or AM, 3D printing can be any of a number of processes used to make a three-dimensional object. A computer lays down successive layers of material into almost any shape from either a software rendering or three-dimensional model. With the push of a button, a 3D CAD idea becomes a physical item.

Depending on the desired use, printed pieces can be made from range of materials including tough high-performance thermoplastics, metals, ceramics, wax, clear polymers, rubberlike or biocompatible photopolymers and chocolate!

According to Javelin Printer Product Manager Doug Angus-Lee, the largest market for 3D printers is in firms interested in making prototypes. This market, he says, accounts for between eighty and ninety percent of the company’s sales.

3D printers are also used to make custom jigs for manufacturing, one-off custom items or components and small-volume production runs. Sectors that have embraced the process are as varied as aeronautics which makes small-volume runs of engine parts for planes, and orthodontics which prints the Invisalign braces – the transparent, incremental aligners that are custom made for each patient’s mouth. Other applications for 3D print technology are seemingly endless and include architectural and construction modeling; industrial design and engineering; components for military, automotive and aerospace industries; food; fashion; custom eyewear and orthotics and even human tissue for biotech and medical applications.

The greatest advantages to the technology are in the lower cost and swifter creation times for this type of manufacturing. Previously, in order to create a prototype part, a company would have needed skilled labour. A mould would have to have been crafted or extensive machining would have been involved.

It does have its limitations. The technology is unsuited for mass production due to the slow print speed and the resolution isn’t always enough to make accurate small parts. Some pieces may still require hand finishing. To make the technology work, designers need to know what they’re doing and that’s where Javelin training comes in.

The company’s sales representatives can help a business to select the right 3D software or 3D printer for its needs. Javelin’s twelve certification programs include industry-specific training and its certified applications engineers and instructors provide support and training in over twenty-five hands-on courses.

The company has a unique approach to training, offering more training courses than most value-added resellers. Javelin’s certified instructors have engineering and design experience and rotate monthly between training and staffing the technical support desk so that their knowledge is kept fresh and skills are continuously improved.

SolidWorks training, using SolidWorks approved content and methods, can be done at any one of Javelin’s training locations across Canada. Classes can be taken as a group in a traditional classroom setting that incorporates hands-on exercises and feedback. The cost-effective approach allows trainees to leave their office environment to concentrate on learning.

For those unable to attend one of the training sessions, interactive and flexible live courses and webinars are offered over the Internet and usually require only a few hours a day. Javelin can also take the training directly to the client via its state-of-the-art mobile classroom with flexible scheduling options.

The advantages are myriad. Since their engineers and designers have the knowledge and skills to use SolidWorks software effectively, Javelin customers have reported a reduction in design times of between fifty and ninety percent. A client can be more confident in the abilities of their team members and win sales by proving to their customers that the team is made up of certified professionals.

Since its inception, Javelin’s quality and service have garnered a host of awards, and it has been a winner of the SolidWorks Support Award on numerous occasions.

In 2011, the company set up shop in a new state-of-the-art facility in Oakville, Ontario. It includes a rapid prototyping lab, media room and 3D theatre. The company’s slogan, “Aim high”, comes to life here in a remarkable atmosphere of innovation and creativity that is second to none. John Carlan, Javelin’s managing director says that the new facility, “offers customers the country’s finest training facilities, while at the same time giving them the opportunity to test out the latest 3D printing technology and experience design concepts in our new 3D theatre. This facility is unlike anything our customers have ever seen before and will allow them to dramatically improve the process and productivity in their businesses.”

Due to its years in the industry, the depth of its technical support database enables it to have all the answers to virtually any questions. Its large technical support team deals with 3,500 SolidWorks customers across many industries and eighty percent of these are small businesses. According to the company, “these are the people that matter to us.” Its team approach means that if the specific account manager isn’t available, other members of the team will help for fast response times.

Javelin’s knowledgeable staff come to the company with a wealth of industry experience and the company puts it to good use. The company’s account managers are all mechanical engineers or technologists who bring real-world design experience to solving client issues. The company also provides its subscription service customers with industry and product information as well as useful SolidWorks tips through its monthly newsletters.

As part of its customized service, it will conduct a preliminary interview with clients in order to tailor-make software and product demonstrations and solutions to fit specific needs. Javelin’s dedication to helping its customers to be successful is reflected in the rate of SolidWorks subscription renewal. Over eighty-five percent of its clients will renew every year.

The company also has a number of initiatives to ensure it is environmentally conscious. “At Javelin, we are constantly finding ways of reducing the carbon footprint for our business and our customers. Utilizing travel-reducing web technology to deliver training and consulting services helps us to minimize the environment impact of human activity and be more environmentally responsible.”

There is also SolidWorks Sustainability, which is an add-on product for SolidWorks MCAD software. It helps designers to better understand the ecological impact of their work and make more environmentally friendly choices. SolidWorks Live Web Training gives customers the ability to interact with an expert on green training.

3D printing is a relatively new technology that is rapidly increasing in popularity and scope, so staying on top of its application possibilities is critical. The technology is almost a new kind of industrial revolution, and the impact on the industrial sector is rapidly expanding. It has a huge potential for the future of consumers, and as Javelin Customer Experience Manager Barb Jarosz says, “Getting the right training is very important for your business success.”