Durex Incorporated is one of the country’s leading contract metal fabrication facilities. Founded on a commitment to providing quality services from machining to stamping and even fabrication, the company offers an innovative approach to the metal demands of the twenty-first century.

~

With a growing U.S. footprint, Durex Incorporated exemplifies the power of homegrown ingenuity. The manufacturing industry has seen substantial fluctuations in the last decade, with many firms choosing to outsource production to other countries. Durex, however, even in the toughest of economic of times, has maintained its position as one of the few U.S. owned and operated competitors in the industry.

“We are a very diversified company. What really continues to set us apart is the diversity of our capabilities; it’s something we are constantly building on here,” said Robert Denholtz, President and CEO of Durex Inc. The company’s broad skill set is an invaluable asset, which can only appreciate over time.

From humble beginnings, Durex grew to the multimillion-dollar industrial leader it is today. Robert Denholtz’s father and a business partner created Durex Inc. in 1946. Following World War II, the pair started a small toy making business out of a garage, eventually creating the moving parts for well-known toy companies across the U.S.

As the company expanded, Durex Inc. transformed into a major metal-based manufacturer. When Robert Denholtz, the current president and CEO, took on the business, diversification took center stage. He explained, “We keep reinventing ourselves along the way. That’s always been part of who we are.”

Today, Durex Inc. products can be seen throughout a wide array of industries including the food service, healthcare and even telecom sectors. In the past five years, the company has seen substantial growth in revenue while it carries out work for the likes of Honeywell, Tyco International, Boeing, Harley-Davidson and General Electric.

In addition to contract manufacturing, Durex Incorporated is also home to three related companies: Creative Serving, a food service equipment line; Sternvent, a line of dust collectors; and White Rail, a company which creates conveyor hangers for the garment and greenhouse industries.

The company’s commitment to diversity and growth is backed by an extensive range of equipment capabilities and knowledgeable staff. Durex’s 120,000 square-foot facility houses the technology necessary to complete all the aspects of metal fabrication.

The company prides itself on taking products from “the cradle to the grave.” When it comes to manufacturing, companies are often highly specialized in one advanced process, but at Durex Inc., each step of the metal manufacturing process is done in-house. “We are a good utility ball player. We have played all the positions.”

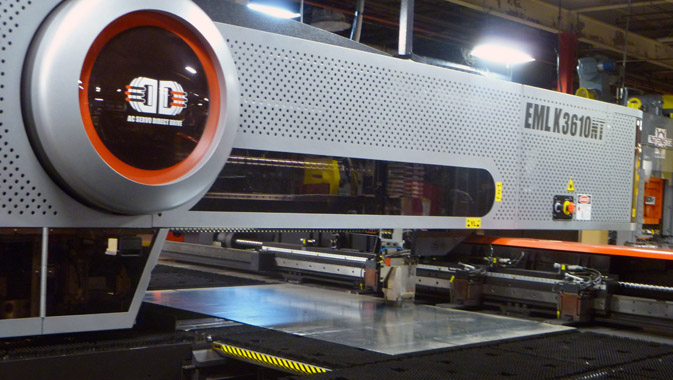

The firm offers a comprehensive solution to the often-disjointed manufacturing process with laser and turret press capabilities, in-house powder coating, electro-mechanical assembly, packaging and over fifty presses with a capacity of up to 400 tons. From machining to fabrication and stamping, Durex has continuously invested into the development of its manufacturing facilities and equipment.

Durex Inc. has been an ISO-9001 certified company for over twenty years, as well as holding certifications from NSF, CSA and UL. These certifications serve as an outside measure of the company’s on-going commitment to customer satisfaction and safe, reliable manufacturing.

Diversification is a distinct advantage of Durex Inc.’s approach, but quite possibly, the firm’s greatest achievement is in attracting, developing and retaining its highly trained staff. In the world today, many companies have lost sight of the importance of valuing employees, but Durex’s success proves that even the most technical industries are only as good as the people that work for them. At Durex this commitment to investing in the expertise of its home-grown professional workforce team remains a central concern.

As most of Durex’s clients have all of their metal needs met in-house, the importance of these professionals is multifaceted. From precision sheet metal fabrication and CNC vertical machining to silk screening and everything in between, Durex has not only the machine power, but also the people power to complete any job.

The union-based manufacturer is home to over 160 highly-trained employees including several engineers, a director of development and, of course, machine operators. “Teamwork is the theme here.” Durex’s staff infrastructure is robust, and, as a result, the company continues to gain widespread industry attention for its personal, customer-centric approach.

Durex Inc.’s footprint across multiple industries has created a culture of excellence and technical know-how. As a result of this experience, the experts at Durex have the knowledge to fix problems before they arise, resulting in higher quality products and more efficient turnaround times. “We have a very strong engineering department. We are very supportive of our customers’ needs on the engineering side because we know metal.”

In recent years, the domestic manufacturing sector has been under immense pressure. When the economic downturn hit, hundreds of manufacturing companies were forced out of business but Durex’s innovative history made failure a non-option. As many manufacturing companies move production overseas, U.S.-based manufacturers are increasingly hard to find, but Durex has remained committed to the U.S. marketplace.

More than ninety percent of the firm’s business comes from U.S. customers, making Durex Inc. not only one of the biggest contract metal fabrication companies on the East Coast, but a significant players in U.S. manufacturing overall.

Durex Inc. has managed to grow domestically, creating diversity through strategic acquisitions and partnerships. No more than 15 percent of Durex Inc. is rooted in any one customer, and less than 20 percent of the firm’s products are based in any industry. Thus, Durex has created a recession-proof corporate culture, which thrives on flexibility. Moreover, Durex Inc.’s diverse range of vertically integrated services complements the increasing number of companies seeking to consolidate their vendor base.

As a result of Durex’s existing infrastructure, many small-to-medium businesses, have found strategic alignment and opportunity in pairing with Durex. As Durex continually seeks out advantageous business partnerships, and acquisition opportunities, the company’s domestic footprint promises to only expand.

Although diversification has certainly benefitted Durex’s longevity throughout the waxing and waning of the national economy, it is the cost-benefit of these diversified services that keeps clients coming back for more. By cutting out the middleman, Durex is able to tailor each contract to detail, while simultaneously cutting down on logistical cost and production time.

Despite the seemingly treacherous setting of the U.S. manufacturing industry in the last ten years, Durex Inc. has emerged an ambitious, home-grown leader. Durex remains a shining example of strategic growth. The company has transformed from a small business, to a national leader, but according to Denholtz, the journey is not over yet. “The thing that I am proudest of is that we have survived, but there is still a lot more to come from Durex.”