FUTEK is a manufacturer of miniaturized load cells, torque sensors, pressure sensors and associated instruments and software. Its products are widely used in the medical, Medtech aerospace, automotive and automation sectors.

~

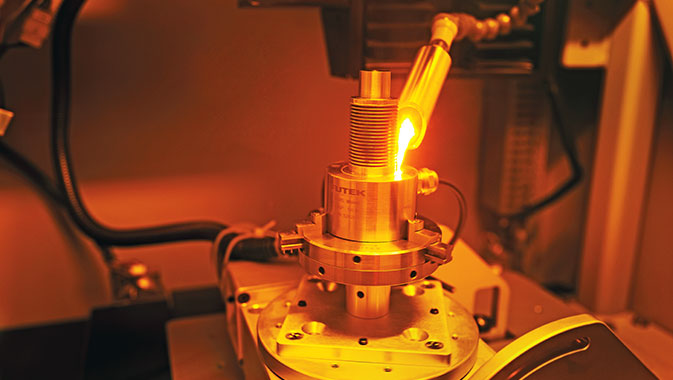

Back in 2007, FUTEK Advanced Sensor Technology, Inc. of Irvine, California, was commissioned by NASA JPL to develop a pair of cryogenic sensors for the Mars Rover Curiosity. The Curiosity was a robotic vehicle, about the size of a car, that NASA planned to use to explore the surface of the Red Planet. The sensors were intended to monitor the force of the Curiosity’s drill bit (which was supposed to drill into the Martian surface and extract samples) and the robot vehicle’s arm.

As the company very well knew, the sensors on the Mars Rover Curiosity had to work perfectly. “Failure was not an option,” recalls FUTEK CEO and President Javad Mokhbery. The company name (pronounced FEW-TEK) is a fusion of the words ‘future’ and ‘technology.’

Besides being millions of miles from Earth, Mars is notoriously inhospitable. “On the surface of Mars, it can get to minus 256 Fahrenheit on the cold side. It warms up to minus 50 on the sunny side,” says Thomas Bowles, Director of Quality Assurance.

If something were to go wrong with the sensors, NASA could not just send a repair team to Mars to fix the problem. With that in mind, FUTEK put its sensors through a hardcore series of tests. Its sensor testing did involve the use of liquid nitrogen and heated environmental chambers to simulate “extreme conditions of very hot temperatures and very cold,” explains Software Director Brandon King.

The Curiosity sensors passed all the tests and were installed in NASA’s vehicle. In the fall of 2011, the Rover Curiosity was blasted into space, landing on Mars on August 6, 2012. Four years later, FUTEK’s sensors continue to work perfectly, note proud company staff.

“We just came up on the four year anniversary [of the landing], and everything still seems to be working fine. We never got that urgent phone call saying, ‘Your sensor is down. We need help’,” says Technical Director Richard Walker.

The two sensors “continue to send back extraordinary science from the surface of Mars,” adds Bowles.

It is quite the accomplishment for a firm founded by Mokhbery in a one-bedroom apartment in Orange County, California back in August, 1985. At first, FUTEK consisted of Mokhbery alone. Then, he was joined by his brother, Mohammad, his wife Zohreh and further family followed. Initially, resources and clients were slim.

Today, FUTEK has “140 plus employees,” says Mokhbery and has achieved international recognition through its products, service, support and involvement with the Mars Rover Curiosity project. While Mohammad passed away in 2013, FUTEK remains a family-owned firm. Mokhbery still runs the company with the support of FUTEK team and assistance of family members and says revenues are “definitely on the rise.”

In addition to sensors, FUTEK offers a full range of services including engineering consulting, calibration, validation and verification. New products include the miniature torque sensor, torque chamber, autoclavable miniature load cell, analogue differential amplifiers as well as a multi-channel digital USB solution as well as new load cells.

FUTEK has numerous certifications including ISO 9001, ISO 13485, ISO 17025, ANSI Z540-1 and complies with International Aerospace Quality Group certification, AS9100, among others. The company is in the process of becoming compliant with RoHS (Restriction of Hazardous Substances) regulations that aim to limit the dangerous substances like lead, cadmium and mercury that are used in electronics and electronic equipment.

FUTEK manufactures most of its components and products. “We do seventy percent of the machining here [and] almost one hundred percent of our critical components. [Products] are machined, completed and assembled here in Irvine, California,” says Walker.

Mokhbery credits the company’s success to a number of factors, including a firm commitment to quality, a family-like corporate culture and a dedication to staying relevant in the fast-paced technology world. ‘We are living in a very dynamic and evolving market … you cannot just follow things by the book,” he explains.

The company focuses on both “educating customers” and “educating ourselves,” adds Mokhbery, a process that “requires being curious.”

As for quality, FUTEK emphasizes “Quality Culture” not “Quality Control” according to Bowles. “Quality control has a bad connotation. Our focus is to do it right the first time. We really have an initiative to get away from all rework. One of our quality goals this year is not doing any rework and not having any scrap … at the forefront of our quality culture is training and skills evaluation. In each department, the training program is extensive. We have a training protocol we use. We do a lot of cross-training [between departments],” says Bowles.

New employees not only have to be talented and willing to embrace quality culture (QC), but they also need to show signs of “emotional intelligence (EQ),” says Mokhbery.

“IQ is important, but EQ is more important, because as you grow, it’s the EQ that helps.” It stimulates open communication, effective teamwork and collaboration, he explains.

EQ is all part of a corporate culture framed around family-values. Mokhbery says traits from successful families, such as trust, empathy and daring are transferable to the working world. In a family situation, you have to trust and respect your partner (just as employees need to trust and respect each other) while at the same time, a successful relationship also requires a degree of risk-taking or daring. In a relationship, this entails taking the plunge to get married, have children or buy a house. At work, daring involves remaining innovative and open to new ideas, says Mokhbery.

Another aspect of FUTEK’s family-oriented culture involves loyalty. Several employees have been working for the firm for over twenty years. Production manager Maitte Galvis, for example, has been with FUTEK for twenty-one years and was, in fact, one of the first employees.

“Everything has changed,” since the founding, she says. For a start, the customer base has grown from “a handful” of end-users to “thousands” of clients. Besides NASA, current clients include Raytheon, MIT, Johnson & Johnson, Medtronics, Edward Lifesciences, and more.

The current workforce at FUTEK is very diverse, with large numbers of foreign-born personnel, adds Galvis.

Walker has been with the firm twenty years. Walker says he has seen, “a lot of growth and maturing [since starting at FUTEK in the mid 1990s]. Growing from a small, mom-and-pop-sized establishment to a mid-sized company that has lots of good structure and quality systems that we’ve implemented.”

Not only is FUTEK’s corporate culture “very family oriented,” the firm boasts “an open-door policy,” adds Walker. When staff face challenges, Mokhbery is “willing to talk, not only to the higher level, but every level. There’s a lot of transparency in the company,” he says.

Among other prominent space-oriented projects, FUTEK has done work on an International Low Impact Docking System (iLIDS) for the International Space Station. The docking system requires load cells intended to detect, guide and dock incoming space vehicles.

FUTEK is also involved with the Orion Multi-Purpose Crew Vehicle (MPCV) for NASA’s space shuttle replacement program. The program is supposed to launch in 2020. FUTEK is participating in the development of safety-sensing sensors for shuttle’s parachute system.

Mokhbery wants FUTEK to grow in the years ahead, but doesn’t believe in hiring more personnel just for the sake of having a big staff. The company plans to continue to “incorporate a lot of automation” in coming years, using robots and automation for various machining tasks, he states.

“Our goal in production is not just to keep adding people, but making them far more effective [with] proper tools and training. In upcoming years, we will be adding more engineers and more technical expertise,” says Mokhbery.

Future areas of expansion include miniaturized products and robotics for the medical technology market. “We will be a major player in minimally invasive autoclavable surgical tools as well as surgical robotics,” says Mokhbery.

One thing that’s not likely to change is the company’s focus on making small numbers of high-end products, as opposed to enormous amounts of cheap components.

“We tend to create products for unique applications. I don’t picture our sensors would be used in a mass-market application. We’re typically focused more on niche markets, like Medtech and automation, some of the high-end manufacturing applications. I don’t picture us making sensors by the millions. Typically, our product line is a high mix of different products but in lower volumes,” says King.

Looking back to the company’s modest beginning, Mokhbery says he isn’t surprised at FUTEK’s success and growth. “I believe in dreaming big … I did anticipate for FUTEK to grow,” he recalls, of the firm’s early days.

The company’s current mood is highly positive, fuelled as it is by the recent anniversary of the Rover Curiosity’s arrival on Mars.

“Obviously, we are very optimistic. When we look at market, I believe we are at the tip of the iceberg. There is so much opportunity in the market. There are lots of unsolved technical challenges out there that companies like FUTEK [can address]. We welcome the challenge,” says Mokhbery.