On a farm in Bracken, Saskatchewan in the 1970s, brothers Greg and Glenn Honey were a couple of determined young farmers who did not let anything stop them from doing what needed to get done. During the winter of 1978-1979, they spent eighteen to twenty hours a day building a giant tractor from the ground up because they needed something bigger for their farm. It was a 500-horsepower beast that was larger than anything on the market.

~

After the tractor was completed, they began to look at other equipment and, not satisfied with what they had for harvesting crops, started looking for ways to improve it to make the work easier. Combines and swathers became next on their list, and as they built, neighbouring farmers took notice and started requesting some of their custom products. By 1979, they and their wives officially launched Honey Bee Manufacturing, starting with the creation of a rod weeder attachment for tillage equipment.

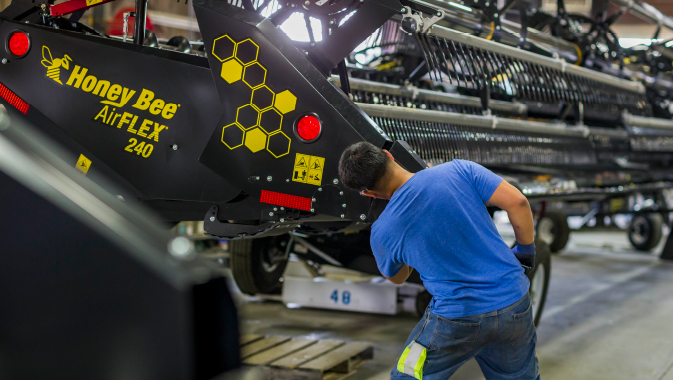

Forty years later, this small family business had expanded not only its product range but also its operations to a 100,000-square-foot production and warehouse facility in Frontier, Saskatchewan. It has become an innovative, world-class manufacturer of draper-style combine and swather headers.

The header attached to the front of a tractor or windrower has what is essentially a huge knife – known as a cutter bar – which saws through the crop being harvested. Behind that, the plants are pulled in and then fall onto a conveyer belt called a draper that moves the crop off to one side and deposits it in neat lines called windrows.

Today the company is still famous in Western Canada for its Honey Bee tractor, which makes annual appearances at trade fairs, and the equipment is constantly evolving and transforming the way traditional farm machinery operates.

Annually, it does between fifteen and fifty million dollars in sales and employs up to two hundred people depending on the season. Its products are sold in Canada, twenty states in the U.S., and in twenty-six countries around the world, including Iceland, Mongolia, Finland, France, England, Pakistan and Australia.

Since its inception, every family member has spent some time working in the business that has been fortunate enough to have many long-time employees who have worked there for anywhere from ten to thirty years. That long-term commitment can probably be attributed to the fact that their employees’ happiness and their sense of belonging in the business is extremely important to the family.

“We’re excited because, in today’s world, there’s a lot of movement, and Greg and Glenn have been able to create an environment here, along with our former General Manager Brad Nelson, that people really enjoy and are a part of,” explained Honey Bee General Manager Jamie Pegg.

And it is not only the employees’ happiness and job satisfaction that is of primary concern to Honey Bee, but also the well-being of the small, three-hundred-person community that has supported it along its forty-year journey.

As with any manufacturing plant, it has faced periods where it has been short on skilled labour. However, it was wise enough to look afar for help and opened the plant to some new Canadians. Many of these people were from the Philippines, and as a result, a great Filipino community has been cultivated in the Frontier area.

“People are the greatest resource that any business can have, and whether those people are family members or whether they are community members or new people to the area – to the business – they’re all very, very important to the business,” stated Pegg. “We all bring different viewpoints, and there are challenges that come with that, but it’s really important to create a working environment where all of those viewpoints are heard and that we end up coming up with the best direction for the company, and it’s really exciting that way.”

Pegg has been with the company for thirteen years, working his way through various departments, including human resources, operations, and sales, until finally becoming the general manager.

Currently, there are five family members working at Honey Bee, including Glenn and Greg, who are on site every day and are often the first people in the door and the last people to leave. These two are the heart of the company – a sentiment that is clearly articulated by everyone who has come in contact with Honey Bee Manufacturing.

“Whether it be the external customer – the end-user – the dealer, or the employees of the company, Greg and Glenn have always served the customers very, very humbly and very, very sincerely, and that’s extended to the people that we work with,” said Pegg.

“They are here innovating, working with our [research and development] team, our engineering team, and overseeing operations and part sales, and just enjoying the business they have been so blessed with,” said Pegg. “With that work ethic and with that care for the product and that care for the people, it just grows in the business.”

The company’s product lines – AirFLEX, AirFLEX SDX, Grain Belt Header, WS Grain Belt Swather, ST Grain Belt Swather, TM Grain Belt Swather, and Rice Belt Header – attach to most combines and many of the windrower tractor units in the market today. Honey Bee customers have stayed loyal because they appreciate the simplicity and effectiveness of the products and the customer service that comes along with each sale.

“We’ve just launched two new products,” said Pegg. “Our AirFLEX product has a solid position in the marketplace and is doing well for us, and we also brought out a new product last fall, the SDX – a soybean table for the Midwest United States, which has been very successful.” It is also in the process of releasing two to three different versions of a rigid table into the marketplace which can be sold to farmers anywhere in the world.

Amidst all the success and innovation, there have also been a variety of challenges with which the company has been faced. Environmental factors with changing weather patterns and the evolution of the farming industry have affected the direction and growth of the company. “Our challenge is to be able to create a machine that can perform well in all those conditions,” stated Pegg.

Technology has become part of the farming equation to ensure food is produced almost faster than we can consume it, but Honey Bee has always been prepared to change the way that its harvest machines are put together to meet the demand, which is quite an accomplishment for a couple of farmers who just built their equipment, not from extensive technical training, but from experience using it.

“I think that their challenge is just getting new products in place, and I think every time that they do it – whether it be with our grain belt header, whether it be with our swather or whether it be with the AirFLEX table today, and the new innovation we have coming in front of that – getting those products out and being successful with them is always a huge, huge challenge,” said Pegg.

Part of that challenge is also to stick with the model of creating simple machinery that does not require complex processes and tools to repair. “Ultimately our concern is for the farmer – the end user of the equipment – that they have a fantastic experience with it and also for our dealers and distributors who make sure our equipment gets out and services the needs of our customers when it’s needed,” said Pegg.

While the company is committed to keeping the product line simple, it has embraced the technological advantages that can make the plant run more efficiently. “Today we see plasmas; we see water jets, and we see welding robots in the plant,” said Pegg. “We’re working on more automation in the plant, which will be robotic moving forward so from that end, a huge evolvement.”

He went on to describe additional technologies that the company has put to use. “From the header itself, you know we see a mechanically-driven product originally, to what became a hydraulically-driven product. We’ve actually advanced that to a new mechanically-driven product, but amplified with electronics and software, and so one of our big challenges today is to make sure that our electronics are as simple as they possibly can be, because we want to make our equipment simple and easy to use for our farmers.”

Technology has also broadened its market reach. “It used to be very, very difficult to do things internationally, but in reality today, I’ve talked to people in Russia and Kazakhstan, in Australia, Brazil, Argentina, and all over the world, and the technology of communication has changed the business significantly,” Pegg explained.

Access to capital and competition in the marketplace has also changed significantly since the company began, both on a local and international level, which has affected the decisions it has made along the way.

“The ag economy certainly has run in cycles over those forty years,” said Pegg. “If you think about starting out a business in the late seventies-early eighties, when interest rates were close to twenty percent, and to think that these gentlemen persevered through that – along with a lot of really great employees – to be able to see a new business through that time, it was fantastic,” he shared.

“I think we’ve also seen, and we’re still seeing today, the changing landscape of dealerships,” continued Pegg. “You know there was a time where every small town had a dealership in place that sold into that community of farmers, and now we see dealerships amalgamating, growing and having fewer locations in some cases to serve people.”

As for the future, there is a succession plan in place to keep the business in the family. “You know, I would say that it started out on the innovation of Greg and Glenn and their family,” said Pegg. “They did things around their farm for themselves and were really happy to share that with neighbours and friends… family has grown into community with the length of time that people spend here, and I think that would be the way that the business would remain a family- and community-based business.” Supporting community has long been a rural value, and neighbouring farmers have always come together and supported each other, rather than competed against one another.

Honey Bee Manufacturing is a business that has achieved international success and recognition, but it took more than the Honey brothers to get it here. “It’s not just them, it’s been a whole bunch of people that have worked with them, worked around them, some that are here, and some that are not here anymore that have helped to raise this company to the level that it is at, and it will require the same thing to move this company forward into the future,” said Pegg.

There is a drive to keep building and growing this business and ensuring its success, and that drive is founded upon faith and a belief that God’s grace has been the reason the family has been able to have the business that they have. For the Honeys, that faith is what will continue to guide their path for future generations.

The plan for the future, according to Pegg, is “to continue to grow the business in a customer-focused way so we never want to lose sight of the farmer and trying to give the farmer a really fun and enjoyable experience. Greg and Glenn, and by an extension Honey Bee, are really proud to serve and to support the agricultural community, and there’s just a strong desire to do that, and I am proud of that fact on behalf of them.”